Copper & Cooper Alloy Business of Mitsubishi Materials has always accommodated needs of customers and expanded its business in line with Japanese industrial development.

While we are the largest company in the Copper & Cooper Alloy Business in Japan, we continue to take our steps forward for future as ever.

Transfer of management to Mitsubishi Goshi Kaisya

Commenced commercial production of ingots by mold casting of copper cathode.

Established with capital of 300 thousand yen, named DAI-ICHI SEIHYO CO., LTD.[ Mitsubishi Shindoh Co., Ltd. ]

Renamed as DAI-ICHI SANGYO CO., LTD.[ Mitsubishi Shindoh Co., Ltd. ]

Commenced manufacturing of copper alloy products (mainly copper and brass rod and sheet) with capital of 200 thousand yen.[ Sambo Copper Alloy Co., Ltd. ]

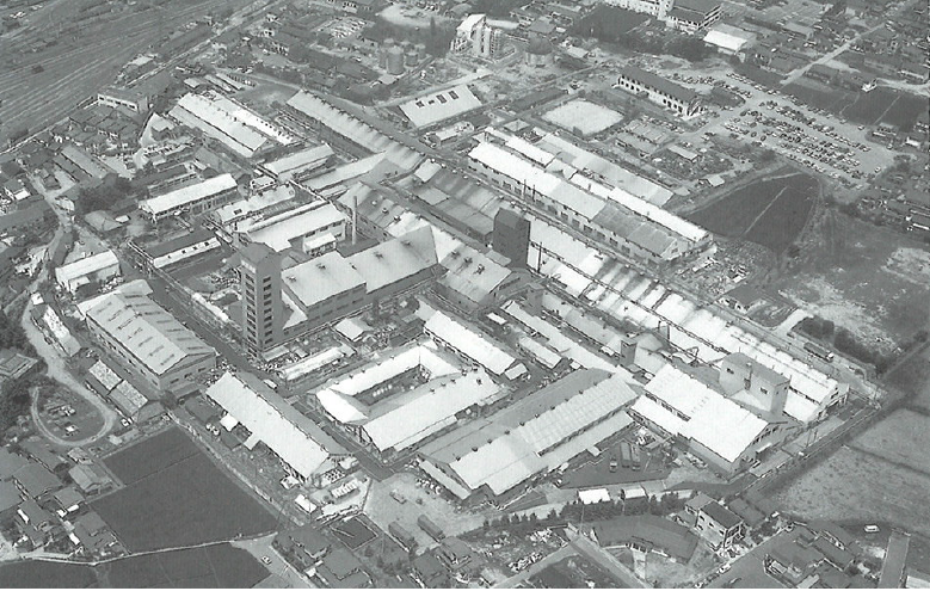

Wakamatsu Factory (currently as Wakamatsu Plant) was established. Nonferrous metal rolling business was started. Capital increased to 2 million yen.[ Mitsubishi Shindoh Co., Ltd. ]

Renamed as NISSO WORKS CO., LTD.[ Mitsubishi Shindoh Co., Ltd. ]

Commenced production of wirerods by hot rolling of copper bar

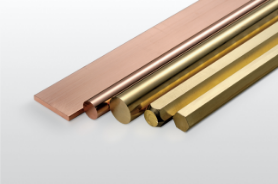

Built status as general copper alloy manufacturer covering all copper alloy products such as sheet and plate, strip, pipe, rod and bar, and wire.[ Sambo Copper Alloy Co., Ltd. ]

plate

plate strip

strip rod and bar

rod and bar wire

wire

Installed industry-first 3,000 ton extruder.[ Sambo Copper Alloy Co., Ltd. ]

Commenced production of wirerods by SCR, which was developed by Southwire Company in the U.S.

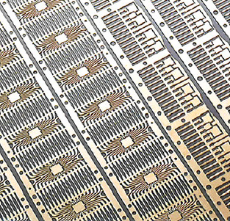

Commenced production of lead frame materials for semiconductors.[ Mitsubishi Shindoh Co., Ltd. ]

Built Technological Research Institute inside Head Office.[ Sambo Copper Alloy Co., Ltd. ]

Commenced production of wirerods by DIP Forming Process, which was developed by General Electric Corporation in the U.S.

Started operation of reversible hot rolling mill[ Sambo Copper Alloy Co., Ltd. ]

Started operation of 12-stage cold rolling mill[ Sambo Copper Alloy Co., Ltd. ]

Installed and started operations of new indirect extruder[ Sambo Copper Alloy Co., Ltd. ]

Begun production of billets and cakes made by Oxygen free copper melted by electric furnace.

Cakes

Cakes Billets

BilletsInstalled and started operations of new horizontal continuous melting and casting machine[ Sambo Copper Alloy Co., Ltd. ]

Established RYOSHINDOH MANUFACTURING (MALAYSIA) SDN. BHD.[ Mitsubishi Shindoh Co., Ltd. ]

Commenced production of ROX® which is oxygen-free copper wirerod by employing copper melting shaft furnace.

Obtained certification of ISO14001 at Sakai Plant.

GOTOH MFG CO., LTD. and GOTOH PHILIPPINES CORPORATION became our subsidiaries.[ Mitsubishi Shindoh Co., Ltd. ]

Developed EcoBrass lead-free brass alloy

Obtained certification of ISO9001 at Sakai Plant.

Obtained the ISO 14001 certification at Wakamatsu Plant.[ Mitsubishi Shindoh Co., Ltd. ]

Transferred forging business to Sambo Forging Co., Ltd.[ Sambo Copper Alloy Co., Ltd. ]

Commenced production of oxygen-free copper billets and cakes by employing copper melting shaft furnace.

Started Copper & Copper Alloy Development Center at Onahama Plant.

Installed and started operations of new No. 2 AP Line[ Sambo Copper Alloy Co., Ltd. ]

March 19, Installed and started opetation of New Rolling Facilities in Sambo Plant.

Qingdao Ecobrass Co., Ltd. was established in Qingdao

Commenced production of copper alloy wires made with ROX

Acquired the Special Products Division of the Luvata Group, which specializes in the processed copper products

Copper and Copper Alloy business of MMC has launched new era.