Has excellent properties of wear resistance and machinability.

Possible to cold work.

Improved strength and wear resistance compared to UH11 by adding Al.

Has highest strength and wear resistance in the UH series.

UH 11 is excellent in the wear resistance and the machinability, and can be also used in cold working. UH 12 is a material has higher strength and higher wear resistance than those of UH 11 by adding Al. UH 13 is a material having the highest strength and wear resistance in the UH series.

It is suitably used for sliding parts such as bearings and gears such as a cylinder block, a shoe, a liner, a thrust metal, a screw nut, a hub wheel, a bush, and pinion gear.

It shows chemical components of UH series. (Representative value)

| Cu | Al | Zn | Pb | Mn | Si | |

|---|---|---|---|---|---|---|

| UH11 | 59.0 | - | Rem. | 1.0 | 2.5 | 0.9 |

| UH12 | 62.0 | 1.5 | Rem. | 0.8 | 2.5 | 0.9 |

| UH13 | 62.0 | 3.0 | Rem. | 0.3 | 3.0 | 1.0 |

It shows the physical properties of the UH series.

| Property | Representative Value | ||

|---|---|---|---|

| UH11 | UH12 | UH13 | |

| Specific Gravity (293K) | 8.3 | 8.2 | 7.9 |

| Coefficient of Thermal Expansion (×10-6/K:293~573K) |

20 | 20 | 20 |

| Thermal Conductivity (W/(m・K):293K) |

101 | 101 | 101 |

| Electrical Conductivity (%IACS:293K) |

18 | 20 | 23 |

It shows the mechanical properties of UH series.

| Property | Representative Value | ||

|---|---|---|---|

| UH11 | UH12 | UH13 | |

| Tensile Strength (N/mm2) |

550 | 650 | 800 |

| 0.2% Yield Strength (N/mm2) |

400 | 450 | 500 |

| Elongation (%) |

35 | 25 | 10 |

| HV | 150 | 180 | 230 |

| HRB | 84 | 88 | 98 |

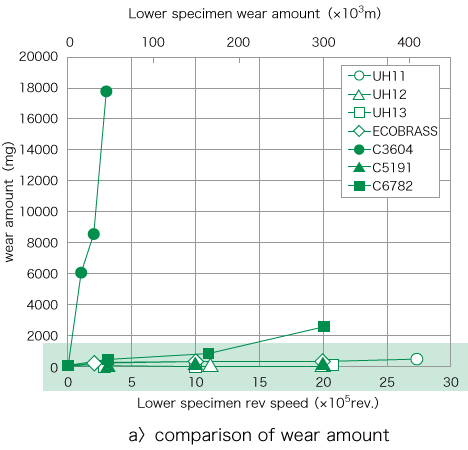

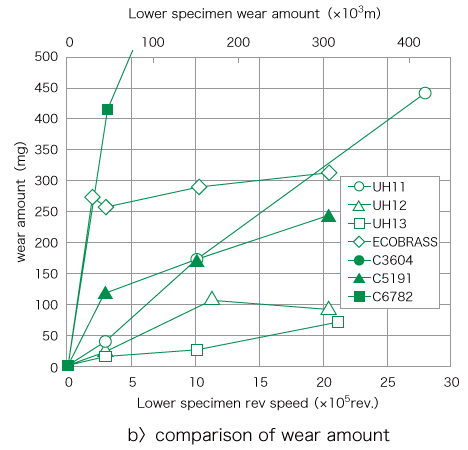

When referring to the wear test results in the Amsler type abrasion test (under lubrication), the reduced wear amount of UH 12 · UH 13 is equal to or less than 1/2 of C5191, and it is possible to confirm the excellent wear resistance.

TEL:+81-6-6355-5101