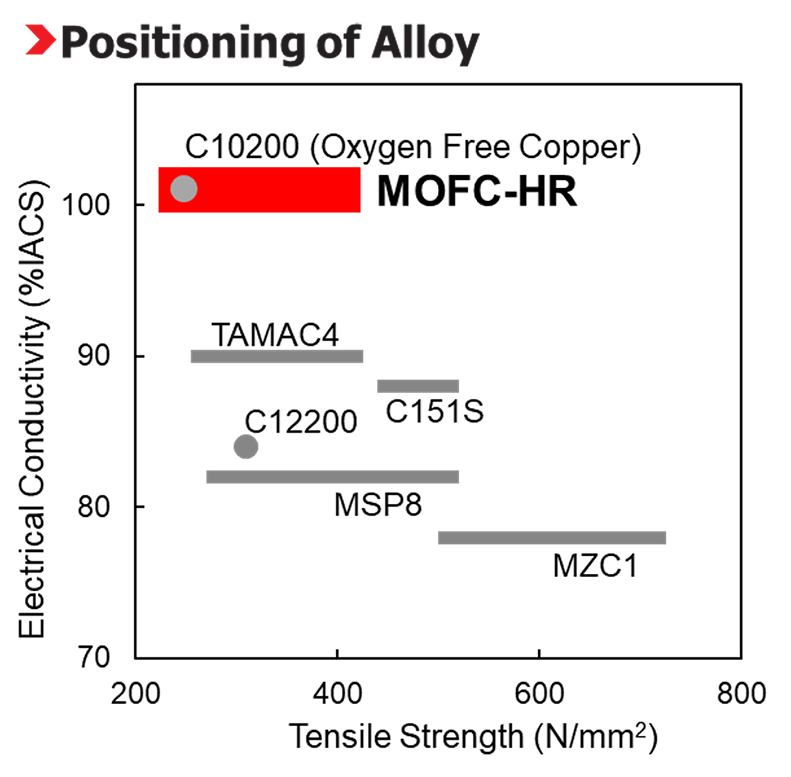

MOFC-HR is an oxygen-free copper with strength and heat resistance enhanced to the world’s highest level, suitable for heat dissipating, high current electronic devices and conductors for EV and next generation energy applications. It is also a replacement material for copper alloys with low electrical conductivity.

It has the electrical and thermal conductivity of oxygen-free copper (C10200) with high strength and superior heat resistance and stress relaxation resistance.

High voltage terminals for automobiles, busbars, charging connectors, relay terminals and sockets, battery tab leads, lead frame and heat sink for power modules

The chemical compositions of MOFC-HR are as follows.

(mass%)

| Cu |

|---|

| 99.96 Min.* |

The physical properties of MOFC-HR are as follows.

| Property | Representative Value |

|---|---|

| Specific Gravity (297K) |

8.94 |

| Coefficient of Thermal Expansion (×10-6/K : 293〜573 K) |

17.7 |

| Thermal Conductivity (W/(m・K) : 293 K) |

391 |

| Volume Resistivity (µΩm) |

0.017 |

| Electrical Conductivity (%IACS : 293 K) |

101 |

| Modulus of Elasticity (kN/mm2 : 293 K) |

119 |

The mechanical properties of MOFC-HR are as follows.

| Temper | Typical Values | |||||||

|---|---|---|---|---|---|---|---|---|

| 1/2H | H | EH | SH | 1/2H t:3.0mm |

H t:1.0mm |

EH t:1.2mm |

SH t:0.2mm |

|

| Tensile Strength (N/mm2) |

245~315 | 275~345 | 315~415 | 355~455 | 246 | 302 | 356 | 403 |

| 0.2% Yield Strength (N/mm2) |

- | - | - | - | 226 | 300 | 351 | 389 |

| Elongation (%) |

15 Min. | - | - | - | 38 | 13 | 4 | 4 |

| Vickers Hardness*1 (HV) |

(60~100) | (85~125) | (95~135) | (105~145) | 81 | 102 | 113 | 123 |

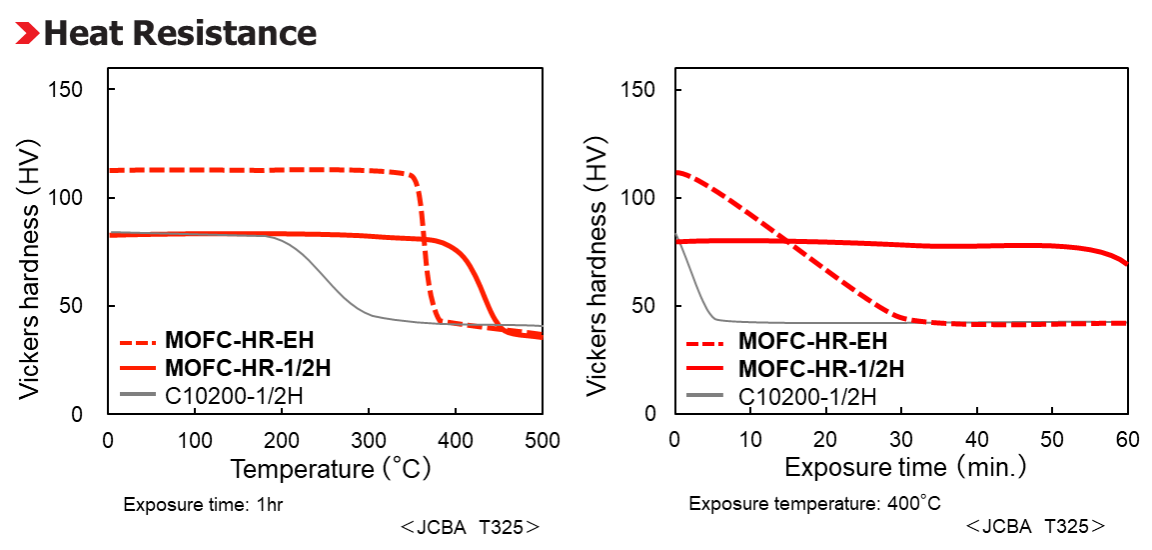

The heat resistance of MOFC-HR are shown on the right.

MOFC-HR can be used in high heat manufacturing process and high heat environment.

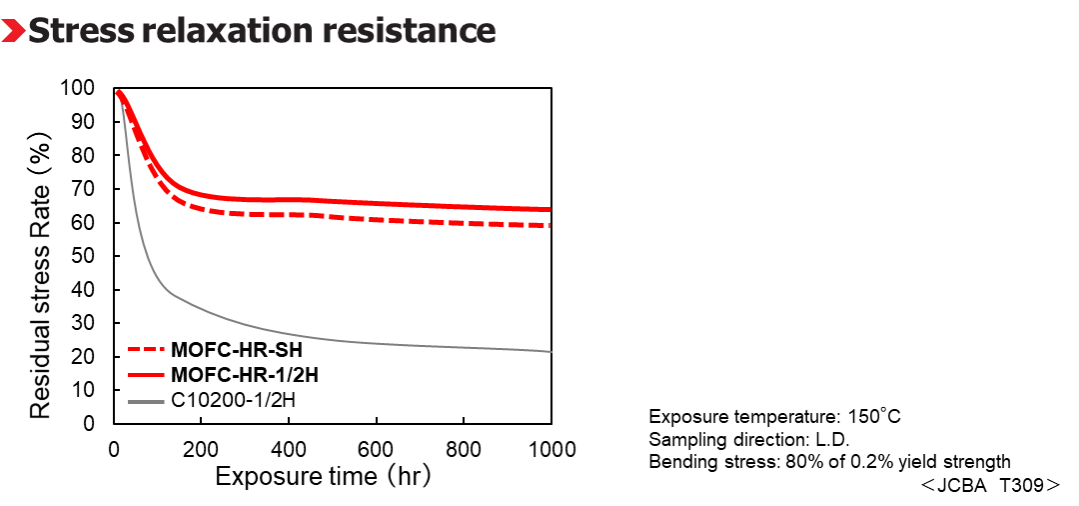

The stress relaxation resistance of MOFC-HR are shown on the right.

MOFC-HR has the electrical conductivity of oxygen-free copper with superior heat resistance, suitable for high voltage terminals and components requiring spring property.

The bendability of MOFC-HR is as follows.

Excellent bendability, suitable for high voltage terminals and busbars.

90° W-Bend, Specimen width=10mm, Load=9.8kN <JCBA T307>

| Temper | Sampling direction (to the L.D.) |

Bending radius (mm) R | R/t | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.0 | 0.1 | 0.2 | 0.25 | 0.4 | 0.6 | 1.0 | 1.6 | 2.0 | 3.0 | |||

| 1/2H t:3.0mm |

0°:Good Way | △ | △ | △ | △ | △ | △ | ○ | ○ | ○ | ○ | 0.0 |

| 90°:Bad Way | △ | △ | △ | △ | △ | △ | ○ | ○ | ○ | ○ | 0.0 | |

| H t:1.0mm |

0°:Good Way | ○ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | 0.0 |

| 90°:Bad Way | ○ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | 0.0 | |

TEL :+81-3-5252-4956