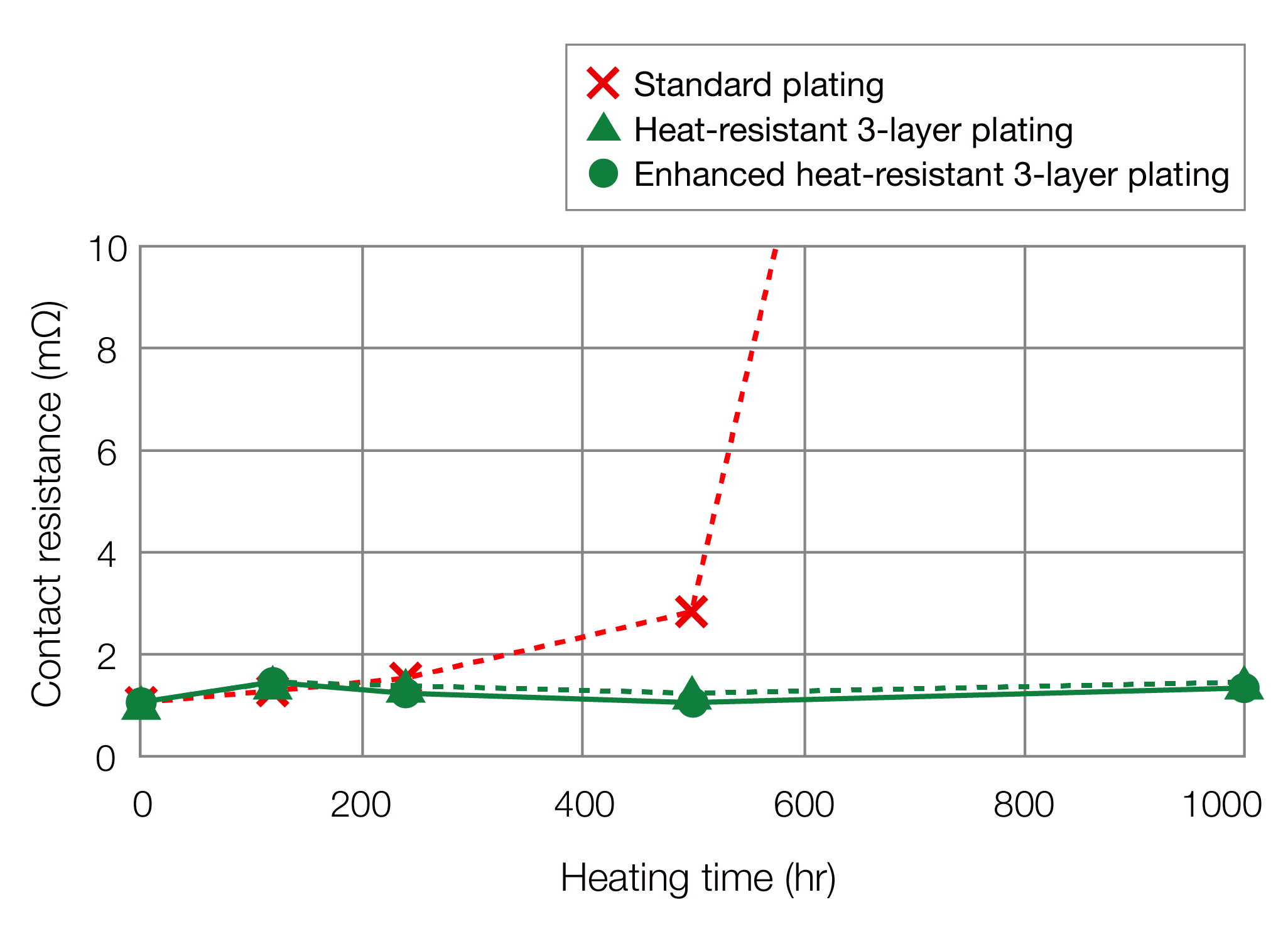

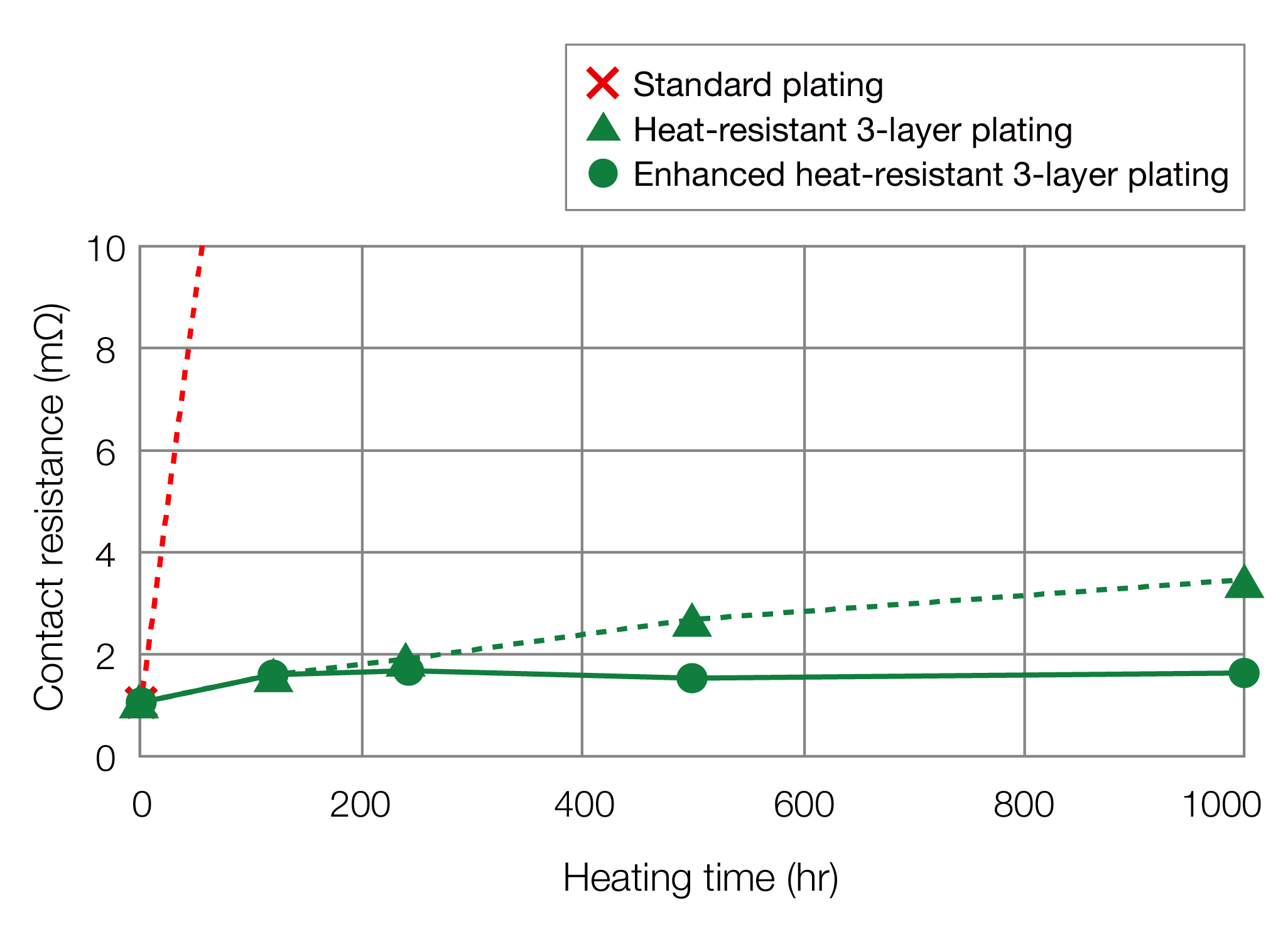

Heat-resistant 3-layer plating possesses the same level of good reliability for electrical connections as Conventional plating and also enables use in higher temperature environments.

Application of this plating in places requiring temperature resistance, where conventionally precious metal plating would have been used, can be expected to lower costs.

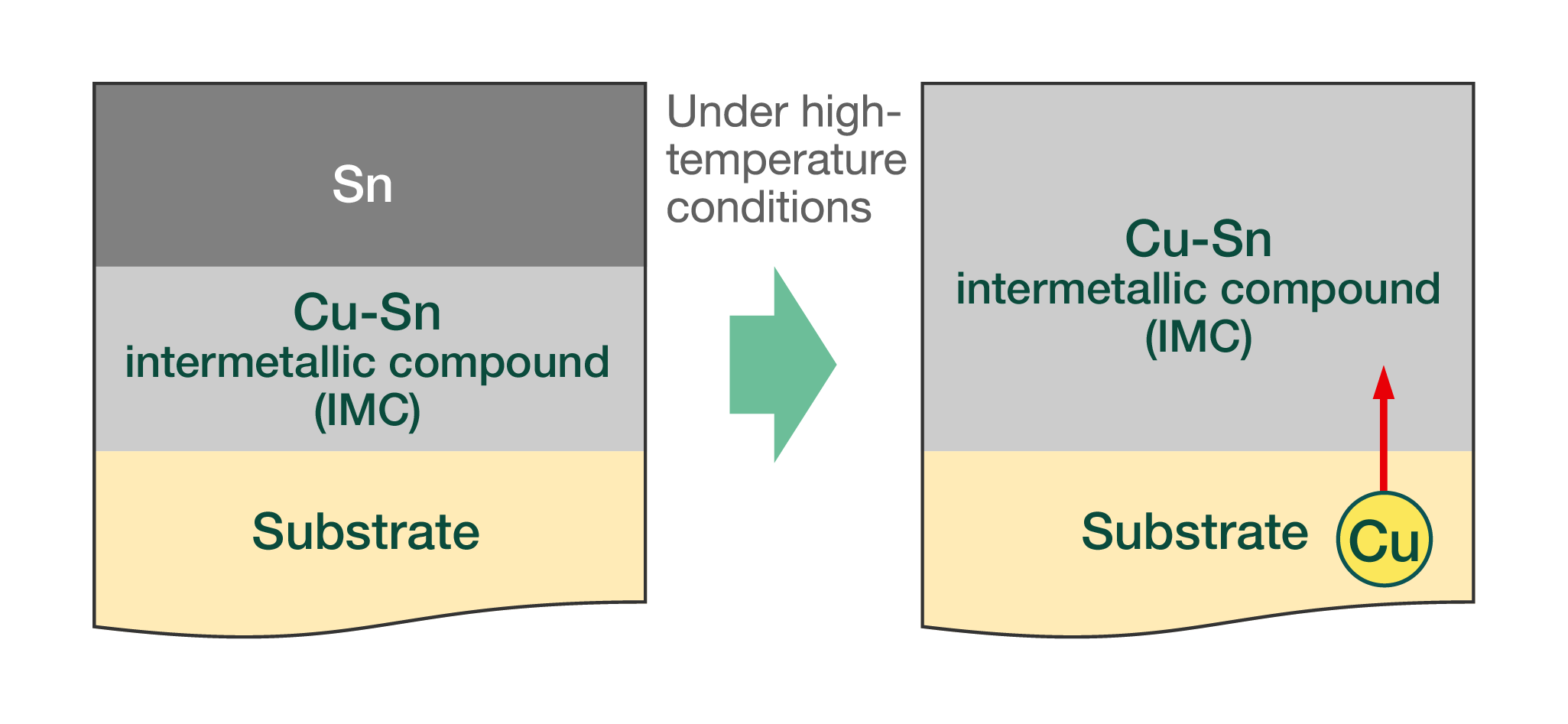

Cu disperses from substrate, Sn forms an alloy

⇒Heat-resistance is degraded

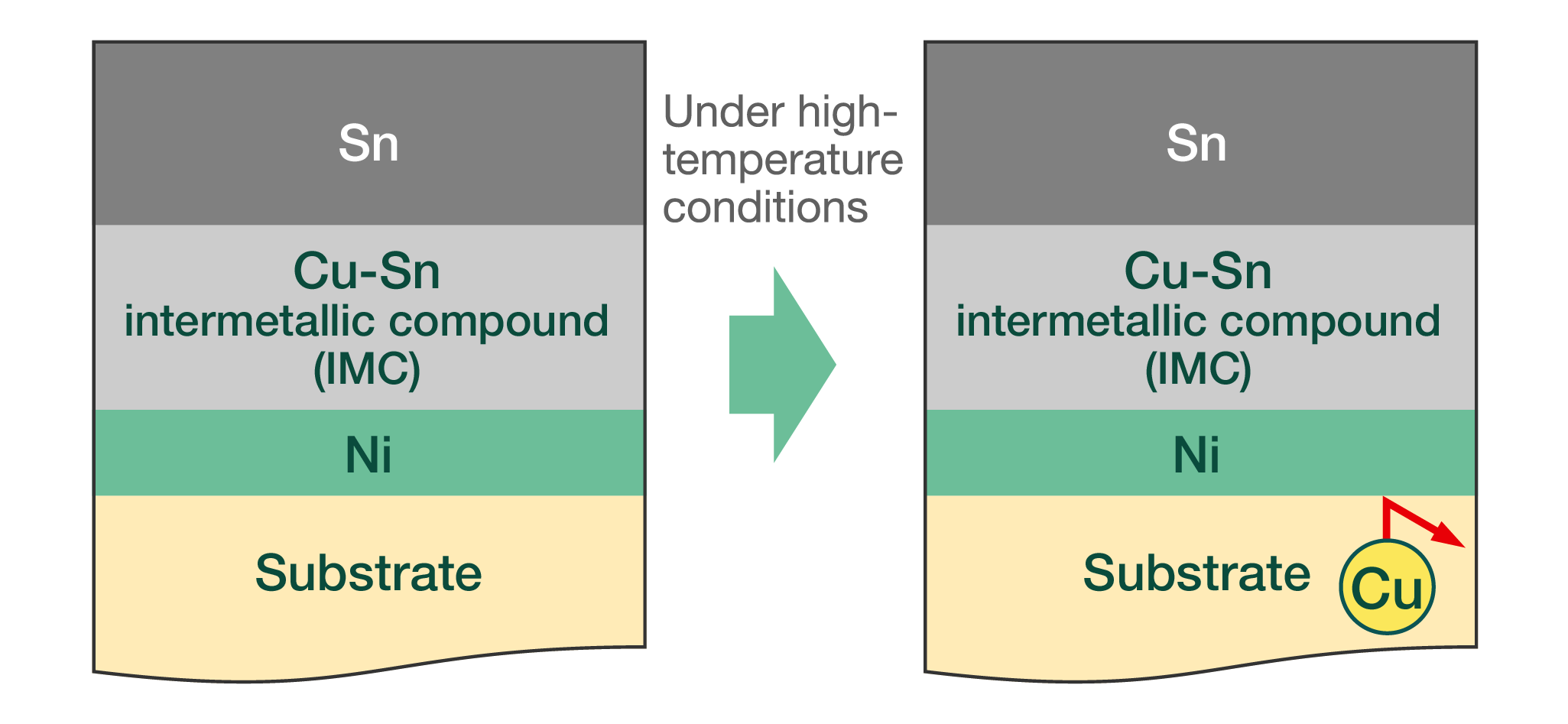

Ni layer suppresses dispersal of Cu, Sn survives

⇒Heat-resistance is maintained

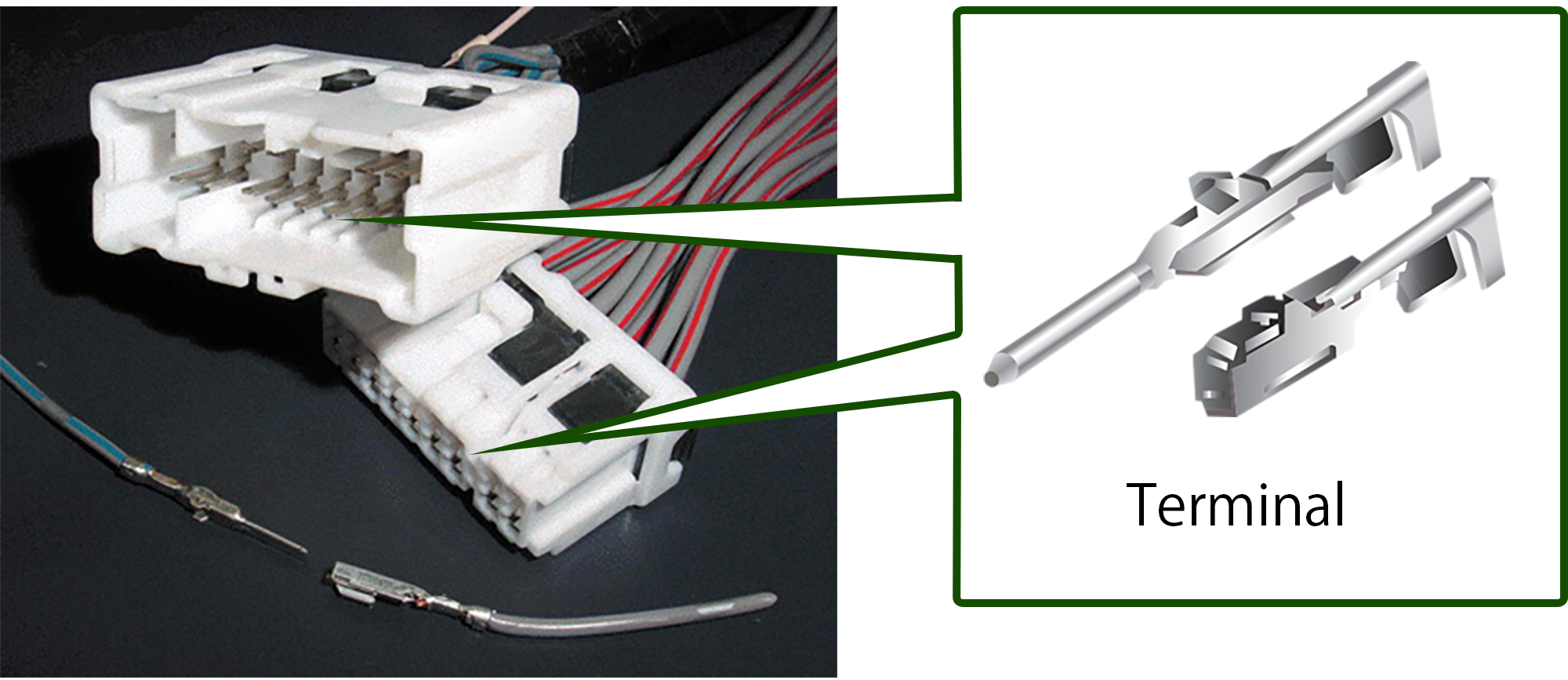

Heat-resistant 3-layer plating is ideal for use on connector terminal materials and bus bars for use in high-voltage for electric vehicles (EVs), engine compartments in conventional automobiles, and other applications where heat resistance is required.

It can also be used as an alternative in places where conventionally precious metal plating would have been used.

Heat-resistant 3-layer plating maintains good reliability for electrical connections even under high-temperature conditions where conventional plating could not be applied.

TEL:+81-3-5252-4956

TEL:+81-72-233-9240