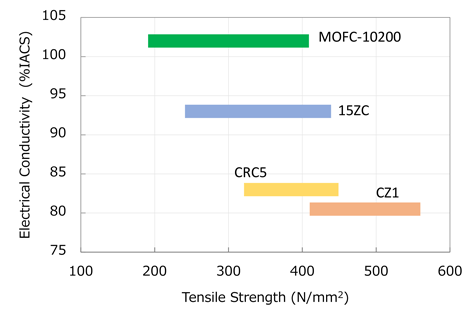

A copper alloy with electrical conductivity close to that of oxygen-free copper, featuring high strength and excellent heat resistance.

A copper alloy with electrical conductivity close to that of oxygen-free copper, featuring high strength and excellent heat resistance. It is used in high-voltage relays, high-voltage terminals, and welding tips.

high-voltage relays, high-voltage terminals, welding tips

The chemical components of 15ZC are as follows.

(Weight %)

| Zr | Cu |

|---|---|

| 0.15 | Rem. |

The physical properties of 15ZC are as follows.

| Property | Representative Value |

|---|---|

| Specific Gravity (293K) | 8.9 |

| Coefficient of Thermal Expansion (×10-6/K:293~573K) |

17.7 |

| Thermal Conductivity (W/(m・K):293K) |

340 |

| Volume Resistivity (μΩm:293K) |

0.019 |

| Electrical Conductivity (%IACS:293K) |

93 |

Mechanical properties of 15ZC are as follows.

| Temper | Rods TMT |

|---|---|

| Tensile Strength (N/mm2) |

400 |

| Elongation (%) |

15 |

| Vickers Hardness* (HV) |

120 |

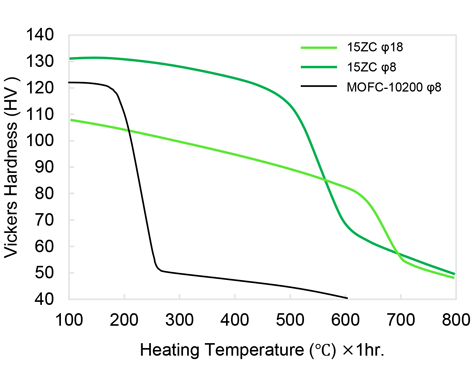

The heat resistance of 15ZC is as follows. 15ZC shows higher heat resistance than MOFC-10200.