GloBrass and ECO BRASS are environmentally friendly materials, complying with RoHS directive, ELV directive and Tap water quality standards.

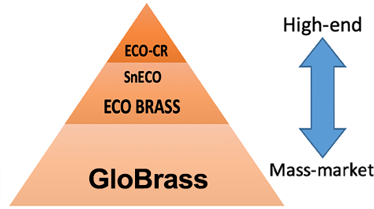

GloBrass is the new material whose copper content is close to general brass, the machinability and the strength are well balanced, it is possible to supply thinner bars, so it is recommended to mass-market segment which lead-containing brass are applied.

ECO BRASS is suitable substitutes for lead-containing brass as well as Austenitic stainless steel (SUS304), since ECO BRASS has a similar strength to stainless steel in addition to characteristics like superior machinability and hydrogen embrittlement resistance.

GloBrass and ECO BRASS contain lead less than 0.09%, complying with RoHS directive, ELV directive and Tap water quality standards, especially NSF61 (Lead elution amount : 5ppb) of Tap water quality standard in the U.S.

Material properties of GloBrass and ECO BRASS are improved by containing Si which does not affect to health while Lead does harm to.

| Enforcement | Area | Name of Regulation | Field | Outline of the Regulation |

|---|---|---|---|---|

| April 2003 | JP | Ministry of Health, Labor and Welfare Ordinance No. 43 of 2002 | tap water | Allowable lead content in tap water was reduced from 0.05mg/L to 0.01mg/L (about 10 ppb). |

| April 2011 | US | NSF14 | tap water | This regulation is related to dezincification corrosion resistance and stress corrosion cracking resistance. |

| July 2012 | US | NSF61 | tap water | Allowable amount of lead dissolved into water was reduced from 15 ppb to 5 ppb. |

| Jan. 2014 | US | S3874 | tap water | The amount of lead contained in plumbing fittings is restricted (weighted average: 0.25%). |

| Dec. 2017 | EU | ELV Directive | automobile | Lead may be contained at 0.1% or less (extension of the exemption allowing inclusion of up to 4.0% lead in a copper alloy has been approved). |

| May 2018 | EU | RoHS Directive | electronics | Lead may be contained at 0.1% or less (extension of the exemption allowing inclusion of up to 4.0% lead in a copper alloy has been approved). |

| Jan. 2021 | EU | Drinking Water Directive | tap water | Allowable amount of lead dissolved into tap water was reduced from 10 ppb to 5 ppb. |

| Sep. 2022 | AU | NSF372 | tap water | The amount of lead contained in plumbing fittings is restricted (weighted average: 0.25%). - - - Transitional period: 3 years |

| Feb. 2023 | US | AB100 (a Californian bill a.k.a. Chan Bill) | tap water | Allowable amount of lead dissolved into tap water was reduced from 5 ppb to 1ppb. - - - Provisional |

| Jan. 2024 | US | NSF61 | tap water | Allowable amount of lead dissolved into tap water was reduced from 5 ppb to 1ppb. - - - Provisional |

Use of a material containing a harmful substance such as lead, marcury, cadmium, or hexavalent chromium for an electrical or electronic component or an automotive component is prohibited by RoHS Directive and ELV Directive.

However, due to an exemption temporarily applied, copper alloys are still allowed to contain up to 4% Pb.

The Consultants of these Directives proposed extension of the exemptions until 2024 in November 2021 with respect to the ELV Directive, and until July 2026 in December 2021 with respect to the RoHS Directive respectively.

The Consultants also indicated that the subjects to which the exemptions are applicable should be more specific and limited in the next review.

Note: The latest information is available on OEKO's website.

Carl-Otto Gensch. Öko-Institut e.V. :"RoHS Evaluations" (https://rohs.exemptions.oeko.info/).

ECO BRASS®️ is the world best-selling lead-free, free-cutting brass.

The alloy's accumulated global sales volume reached 300,000 tons in 2019.

GloBrass is the new material whose copper content is close to general brass, the machinability and the strength are well balanced, it is possible to supply thinner bars, so it is recommended to mass-market segment which lead-containing brass are applied.

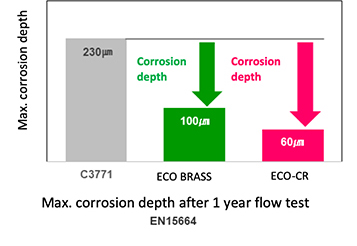

ECO BRASS series are ECO BRASS, SnECO and ECO-CR, SnECO is superior for erosion resistance*1, ECO-CR is outstanding for corrosion resistance*2. Each brass is applied to Automotive parts, Electrical parts and Faucet parts etc.

Faucet parts etc. : Water meter case, Faucet fittings, Sprinkler head

Automotive parts : Solenoid valves, Turbocharger bearings, Brake parts, Relief valve, Temperature sensor, Insert nuts, Tire valves

Electrical parts : 2-3 way valves / Flare nuts / Terminals for Air conditioners

Watch parts : Watch crowns, Case

| Type | Corrosion resistance | Erosion resistance | Application | ||

|---|---|---|---|---|---|

| Faucet parts | Automotive parts | Electrical parts | |||

| GloBrass | Average | Average | Average | Good | Good |

| ECO BRASS | Good | Good | Good | Good | Good |

| SnECO | Good | Excellent | Excellent (Fast flow) |

- | - |

| ECO-CR | Excellent | Good | Excellent | - | - |

| Lead-containing brass, C3604 | Average | Average | Average | Good | Good |

Each Characteristic of GloBrass and ECO BRASS is as follows.

Various Characteristics of GloBrass are superior to Lead-containing brass, the electrical conductivity of GloBrass is higher than Phosphor bronze,

it is applicable for terminals which transfer electric signals.

ECO BRASS series has well balanced performance and similar strength to Austenitic stainless steel (SUS304).

| Type | Tensile strength | Wear resistance | Corrosion resistance | Machinability | Forgeability | Castability | Electrical conductivity (%IACS) |

|---|---|---|---|---|---|---|---|

| GloBrass | Good | Good | Average | Good | Excellent | Good | 16 |

| ECO BRASS | Good | Good | Good | Good | Good | Good | 8 |

| SnECO | Good | Good | Excellent | Good | Good | Good | 8 |

| ECO-CR | Good | Good | Excellent | Good | Good | Good | 8 |

| Lead-containing brass, C3604 | Average | Average | Average | Good | - | - | 26 |

| Lead-containing brass, C3771 | Average | Average | Average | Good | Good | - | 27 |

| Austenitic stainless steel (SUS304) | Good | Excellent | Good | Average | Average | - | 2 |

Chemical compositions and Registered Standard number are as follows.

(Weight %)

| Type | Shape | Standard number | Cu | Si | P | Sn | Pb*1 | Cd*1 | Zn | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CDA | JIS | EN | |||||||||

| ECO BRASS | Bar | C69300 | C6932 | CW724R | 75.5 | 3.0 | 0.08 | <0.1 | <0.09 | <0.0075 | Rem.*2 |

| Casting | C87850 | CAC804 | CB768S | 76.0 | 3.0 | 0.08 | <0.1 | <0.09 | <0.0075 | Rem.*2 | |

| SnECO | Bar | C69310 | C6931 | - | 76.0 | 3.0 | 0.08 | 0.5 | <0.09 | <0.0075 | Rem.*2 |

| Casting | C87870 | CAC804 | - | 76.0 | 3.0 | 0.08 | 0.5 | <0.09 | <0.0075 | Rem.*2 | |

| ECO-CR | Bar | - | - | CW724R | 76.3 | 3.2 | 0.09 | 0.2 | <0.09 | <0.0075 | Rem.*2 |

| GloBrass | Bar | C68370 | - | - | 62.5 | 1.0 | 0.07 | <0.2 | <0.1 | <0.0075 | Rem.*2 |

GloBrass and ECO BRASS are supplied as following shapes.

Bar, Rod Bar, Rod |

Forged products Forged products |

Ingot for casting Ingot for casting |

Continuous casting rod Continuous casting rod |

Continuous casting tube Continuous casting tube |

|

|---|---|---|---|---|---|

| GloBrass | Available | Available | Available | - | - |

| ECO BRASS | Available | Available | Available | Available | Available |

| SnECO | Available | Available | Available | Available | Available |

| ECO-CR | Available | Available | Available | - | - |

Physical properties are as follows.

Typical values

| Property | GloBrass | ECOBRASS | Lead-containing brass C3604 |

Bronze-casting CAC406 |

|---|---|---|---|---|

| Specific Gravity g/cm3 |

8.3 | 8.3 | 8.5 | 8.8 |

| Thermal Conductivity W/m・K |

73 | 35 | 114 | 70 |

| Electrical Conductivity %IACS |

16 | 8 | 26 | 15 |

| Coefficient of Thermal Expansion ×10-6/℃ |

19 | 20 | 21 | 18 |

| Liquidus temperature ℃ |

880 | 890 | 900 | 1010 |

| Solidus temperature ℃ |

865 | 855 | 885 | 860 |

Mechanical properties are as follows.

| Property | GloBrass | ECO BRASS | Lead-containing brass C3604 |

Stainless steel SUS304 |

|---|---|---|---|---|

| Tensile Strength MPa |

625 | 650 | 435 | 660 |

| 0.2% Yield Strength MPa |

470 | 420 | 295 | 310 |

| Elongation % |

20 | 20 | 25 | 55 |

| Hardness HV |

(185) | (200) | (140) | (160) |

| Property | ECO BRASS | Bronze-casting CAC406 |

|---|---|---|

| Tensile Strength MPa |

400 | 220 |

| 0.2% Yield Strength MPa |

170 | - |

| Elongation % |

20 | 15 |

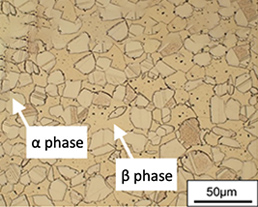

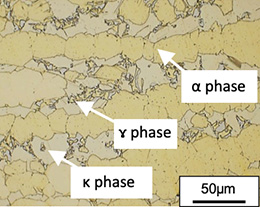

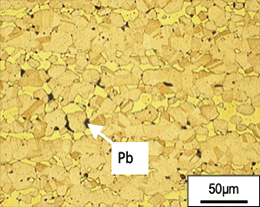

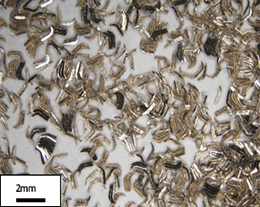

The chips of C3604 are cut off because of stress concentration on Pb particles which are soft and low melting temperature.

On the other hand, the chips of GloBrass are cut off due to stress concentration on β phase. The chips of ECO BRASS are cut off because of stress concentration on κ・γ phases which are hard.

GloBrass and ECO BRASS are applicable for dry cutting, because it's Lead-free. If the chips are not cut off under the same cutting conditions of C3604, we suggest that higher feed rate and lower cutting speed could be effective.

Furthermore, if breakage of cutting edge occurs, cutting edge with honing (small radius) could be one of the solution, such as recommended tools for stainless steel.

|

GloBrass

|

ECO BRASS

|

Lead-containing brass

C3604 |

|

|---|---|---|---|

| Metal structure |

|

|

|

| Chips |

|

|

|

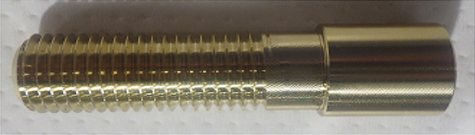

One of the test results is as follows, it was possible to machine GloBrass, ECO BRASS under the same cutting conditions as Lead-containing brass C3604.

The cycle time of GloBrass and ECO BRASS was shorter than that of Austenitic stainless steel (SUS303) because of the higher cutting speed and feed rate.

The video is as follows. (https://youtu.be/X2Ie3rsLKu0)

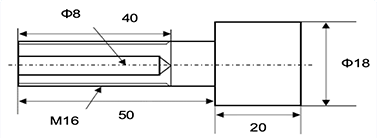

Part after machining Φ20mm Bar (GloBrass)

| Process | Cutting tools* | GloBrass, ECO BRASS C3604 (Dry cutting) |

Austenitic stainless steel SUS303 (Wet cutting) |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Holder | Insert | Rev. (min-1) |

Cutting speed (m/min) |

Feed rate (mm/rev) |

Rev. (min-1) |

Cutting speed (m/min) |

Feed rate (mm/rev) |

||

| 1 | Facing | SDJCR1212M11 | DCMT11T304-LM (VP15TF) |

2122 | 120 | 0.1 | 1768 | 100 | 0.1 |

| 2 | Leading-drill | DLE1000S100P090 | - | 2785 | 70 | 0.07 | 1194 | 30 | 0.05 |

| 3 | Drilling | MVS0800X05S080 | - | 3183 | 80 | 0.1 | 2387 | 60 | 0.1 |

| 4 | Turning | SDJCR1212M11 | DCMT11T304-LM (VP15TF) |

1989 | 100 | 0.1 | 1592 | 80 | 0.1 |

| 5 | Threading | MMTER1212H16-C | MMT16ERG60-S (VP15TF) |

700 | - | 2 | 700 | - | 2 |

| 6 | Turning | SDJCR1212M11 | DCMT11T304-LM (VP15TF) |

1768 | 100 | 0.1 | 1415 | 80 | 0.1 |

| 7 | Cutting-off | GYSR1212JX00-D13 | GY2M0200D020N-GS (VP20RT) |

2000 | - | 0.1 | 2000 | - | 0.1 |

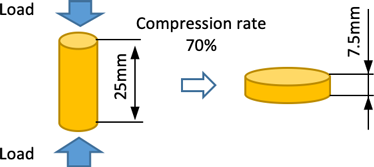

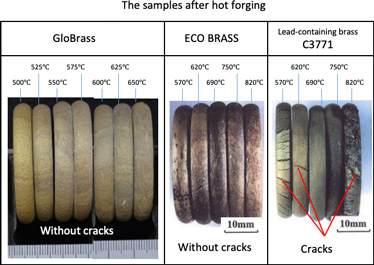

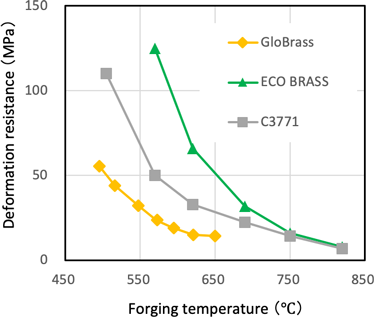

The deformation resistance of GloBrass is lower than Lead-containing brass C3771, so any cracks did not occurred.

GloBrass has well forgeability, the proper temperature is 580~650℃. However, C3771 cracked below 620℃ and at 820℃.

On the other hand, suitable temperature of ECO BRASS is 700~760℃, in which the deformation resistance is low.

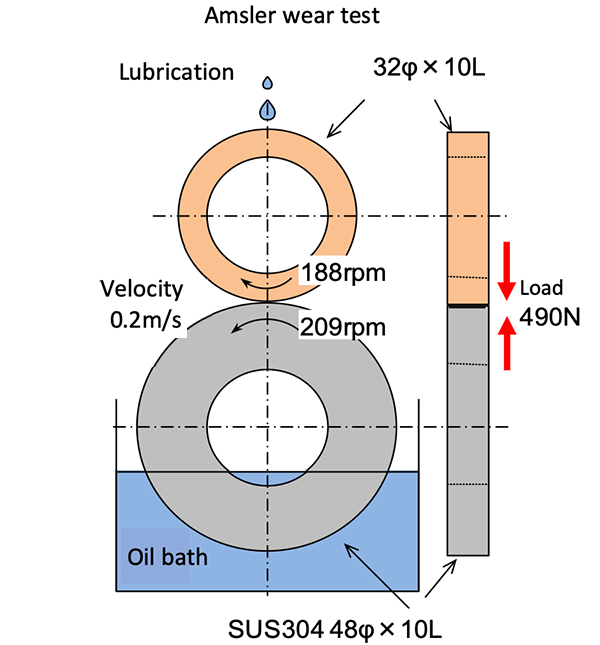

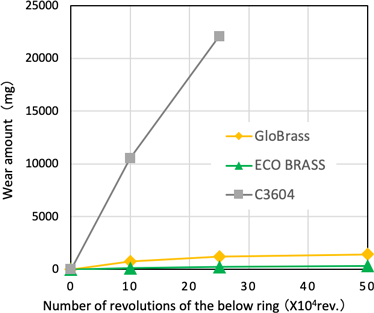

Wear amount of GloBrass or ECO BRASS is smaller than C3604 during the Amsler wear test with the lubrication.

Lubrication conditions :

Silicon oil,

Dripping and oil bath

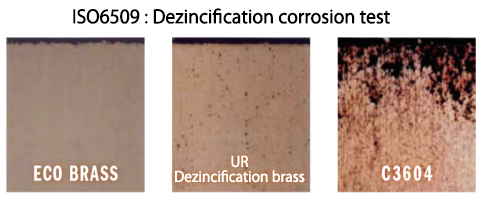

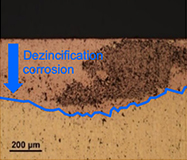

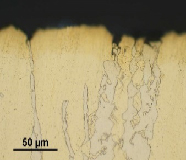

ECO BRASS shows excellence in Dezincification corrosion resistance, because ECO BRASS contains little Zn, and no low β phase in terms of electrochemical in the matrix.

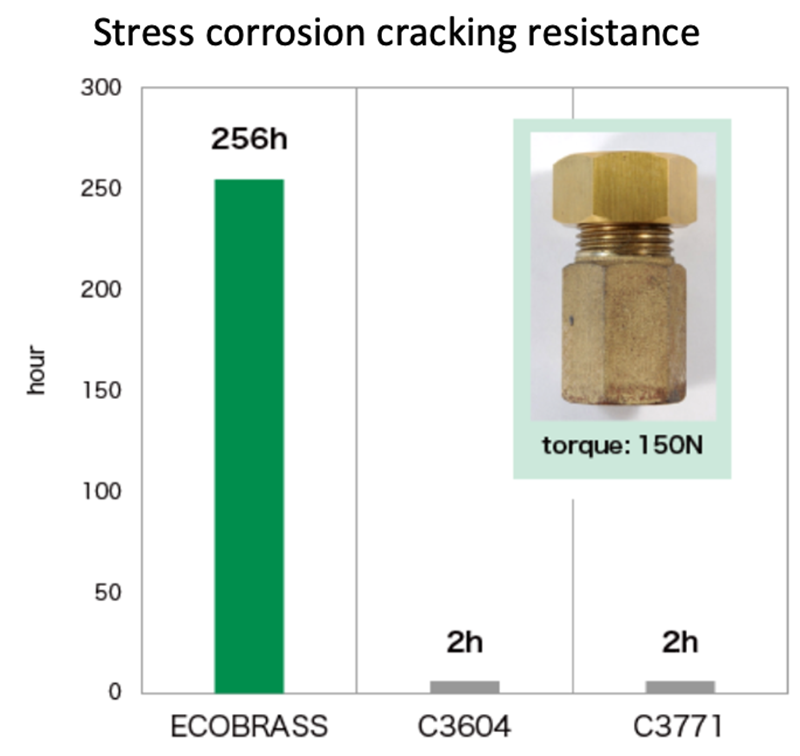

ECO BRASS has superiority in stress cracking resistance, since its composition of low Zn and 3% Si improves effectively for the performance.

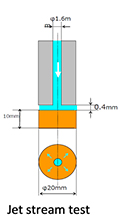

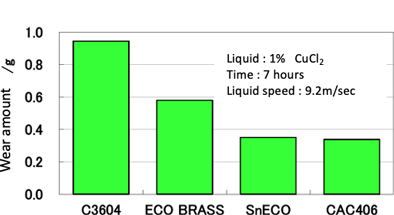

Wear amount of SnECO is lower than C3604, and similar to CAC406(Bronze), because addition of Sn is effective for the corrosion resistance.

ECO-CR has the best corrosion resistance in ECO BRASS series, ECO-CR is recommended for localized corrosion of normal ECO BRASS.

C3604

C3604

ECO-CR

ECO-CR

ISO6509 : Dezincification corrosion test

TEL:+81-3-5252-5202

TEL:+81-6-6355-5101