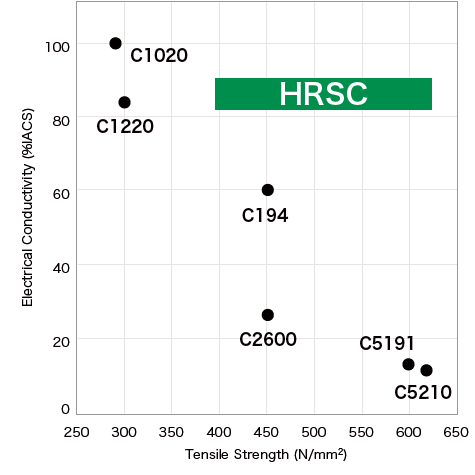

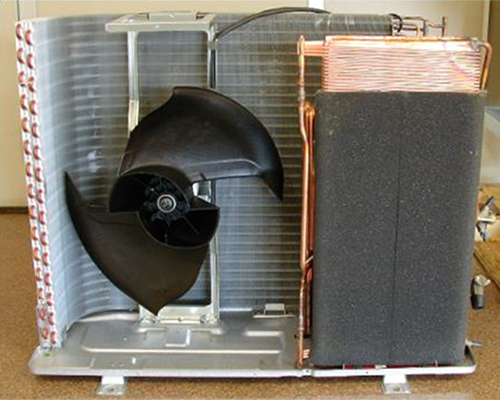

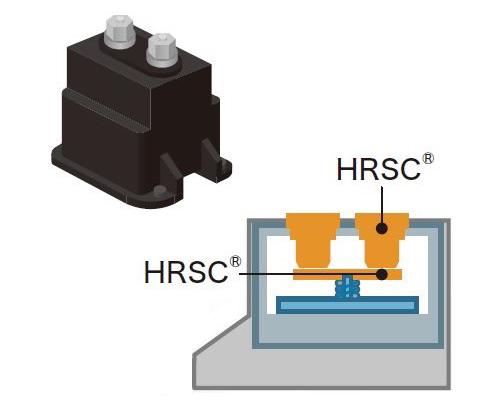

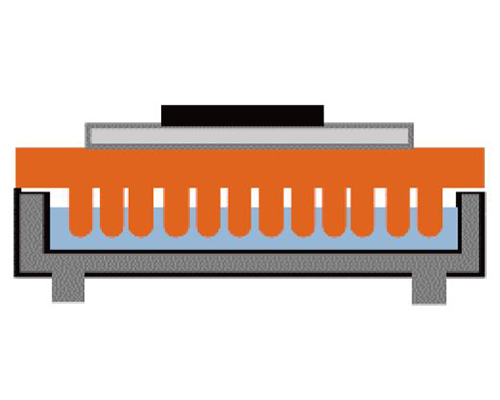

HRSC has high thermal conductivity and high electrical conductivity.

And it has an excellent balance of strength and workability.

HRSC maintains initial strength inspite of heat -treatment at 800℃×10min due to the grain grow is suppressed.

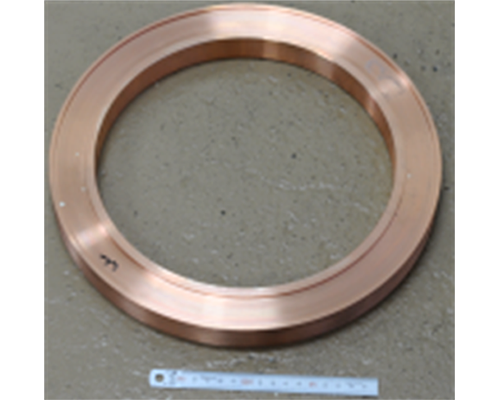

HRSC is able to be provided at various shapes (such as plate,strip,rod/bar,pipe,wire and hot forged).

HRSC is a heat-resistance copper alloy .And it has high erectric conductivity (equal to Phosphorus deoxidized copper‐C1220) and strength (par with brass‐C2600 and Phosphor bronze‐C5191) .

(Weight %)

| Cu | Co | P | Sn | Ni |

|---|---|---|---|---|

| Rem. | 0.27 | 0.08 | 0.04 | 0.04 |

(Weight %)

| Property | Representative Value |

|---|---|

| Specific Gravity (293K) | 8.9 |

| Coefficient of liner expansion( ×10-6/K:293~573K) | 17.1 |

| Thermal Conductivity(W/(m・K):293K) | 330 |

| Electrical Conductivity(%IACS:293K) | 85 |

| Modulus of Elasticity(kN/mm2 : 293K) | 125 |

| Poisson Ratio(293K) | 0.33 |

| Shape | Strip* | Rod/Bar | Forging |

|---|---|---|---|

| Size(mm) | 0.65 | Φ10 | - |

| Temper | H | H | As aged |

| Tensile Strength (N/mm2) |

525 | 540 | 380 |

| 0.2% Yield Strength (N/mm2) |

510 | 520 | 255 |

| Elongation (%) |

5 | 15 | 40 |

| Vickers Hardness (HV) |

(160)* | 165 | 115 |

| Electrical Conductivity (%IACS) |

85 | 85 | 85 |

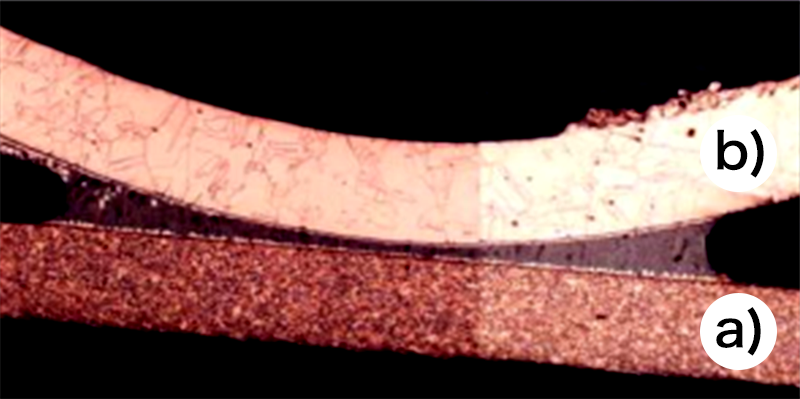

Even after brazing heat treatment (800 °C x 10 minutes), there is no coarsening of the metal structure and it has thermal stability compared with C1220.

Heat treatment condition: 800 °C × 10 min (equivalent condition for brazing in furnace)

a) HRSC (G.S. 10 µm) 0.2% proof stress of 110 N/mm2

b) C1220 (G.S. 100 µm) 0.2% proof stress of 22 N/mm2

Heat resistance: cross-sectional structure and strength after brazing heat treatment

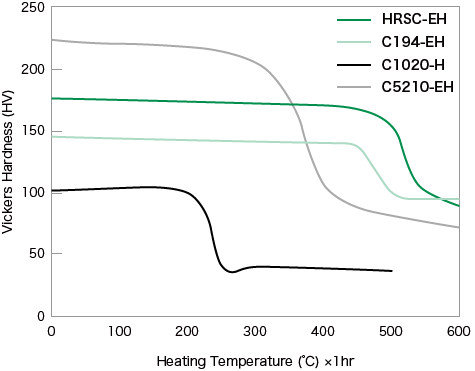

Heat resistance: isochronal annealing curve

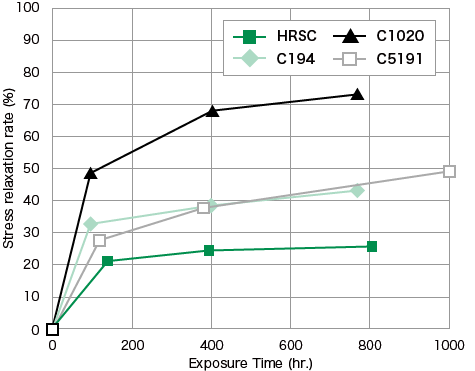

Test method: JCBA-T309: 2004

Exposure temperature:150℃

Bending stress: 0.2% yield strength 80%

Evaluation: The mean value of TD and LD

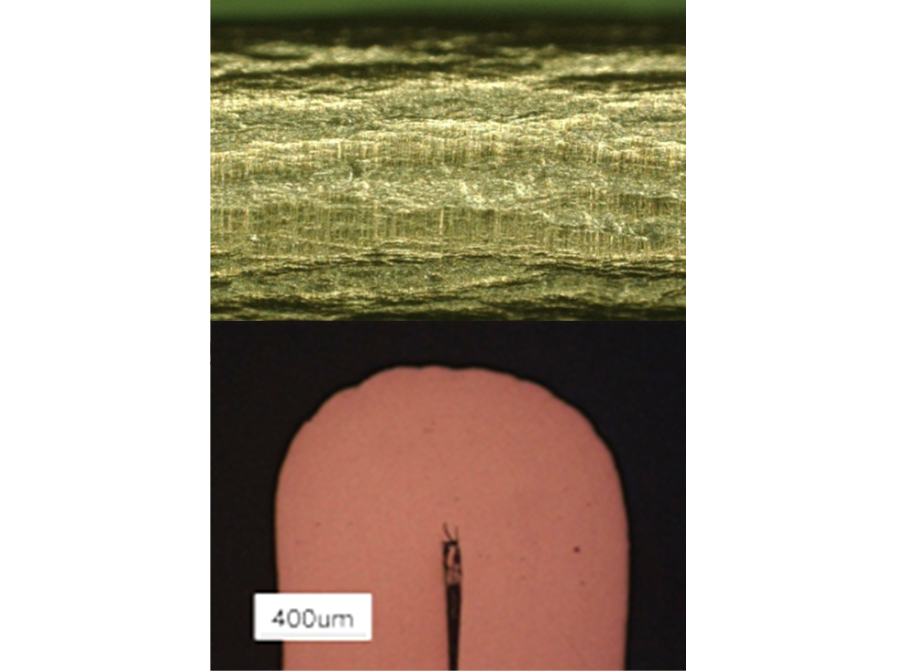

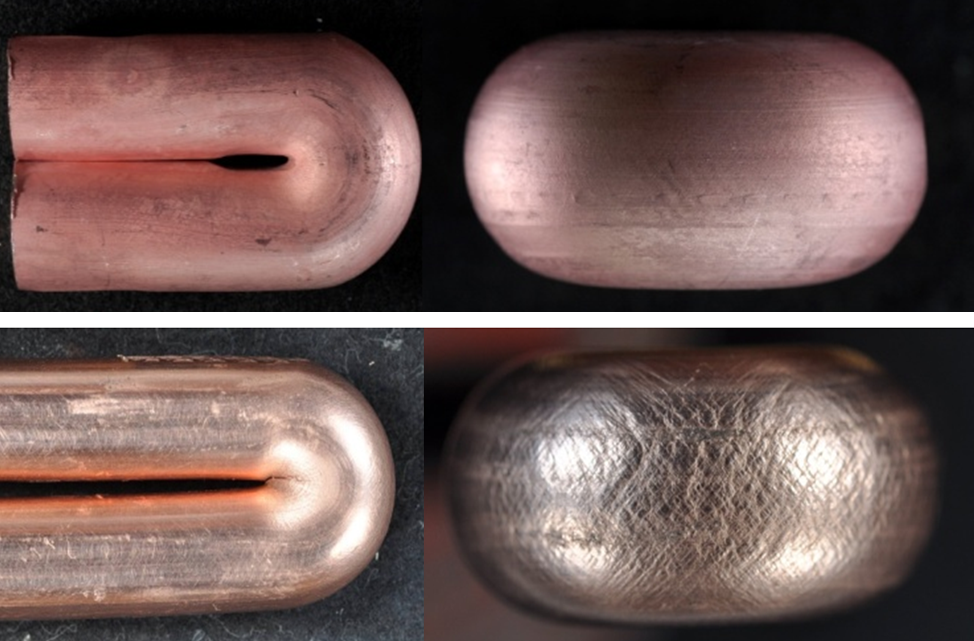

It has good bending workability and it can cope with various processing.

| Temper | Sampling Direction | Bending Inside Radius (mm) R | Evaluation | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.0 | 0.1 | 0.15 | 0.2 | 0.3 | 0.4 | 0.6 | 0.8 | 1.0 | 2.0 | R/t | ||

| H | G.W. | ▲ | ▲ | △ | △ | △ | △ | ○ | ○ | ◎ | ◎ | 0.2 |

| B.W. | ▲ | ▲ | ▲ | ▲ | ▲ | △ | △ | △ | ○ | ◎ | 0.6 | |

| EH | G.W. | ▲ | ▲ | ▲ | ▲ | △ | △ | △ | ○ | ○ | ◎ | 0.5 |

| B.W. | ▲ | ▲ | ▲ | ▲ | ▲ | ▲ | △ | △ | △ | ○ | 0.9 | |

Bending test 180°(B.W.) R/t=0

Temper: H, Thickness0.64mm

Strip: 180°adhesion bending

Rod/Bar Temper: 0, φ25mm

Bar: 180°bending appearance

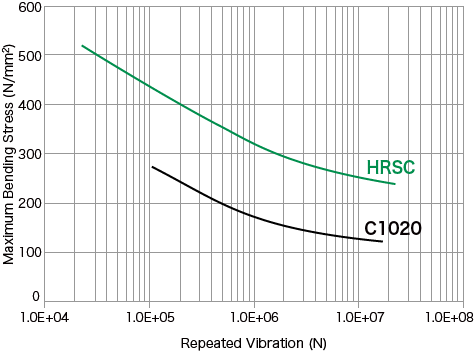

It has good fatigue property.

TEL:+81-3-5252-4956

TEL:+81-72-233-9240

TEL:+81-3-5252-5202

TEL:+81-6-6355-5101