Corson alloys has an excellent balance of strength and electrical conductivity due to Ni -Si intermetallic compounds precipitated in the matrix.

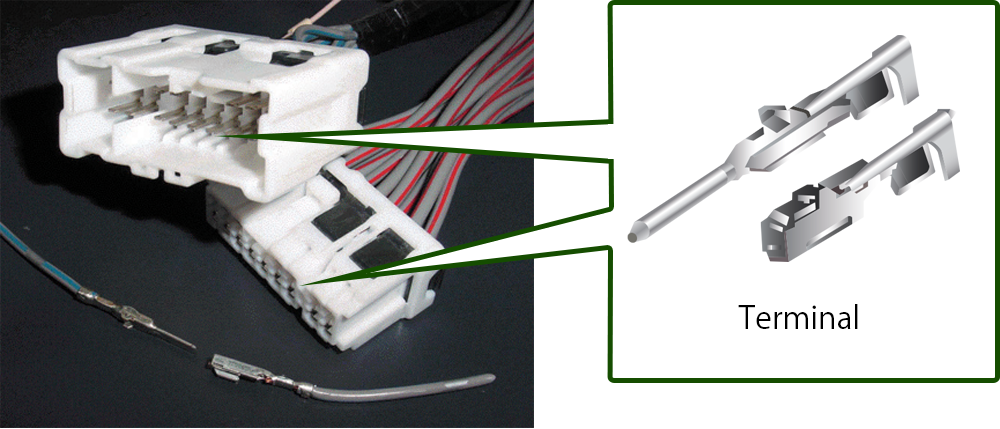

Automotive terminals · connectors, consumer terminals · connector relays, IC sockets, breakers, lamp sockets, CPU sockets

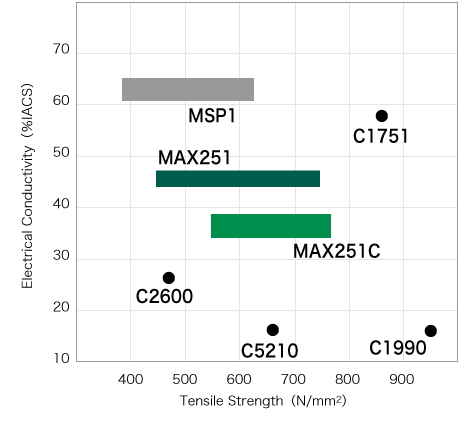

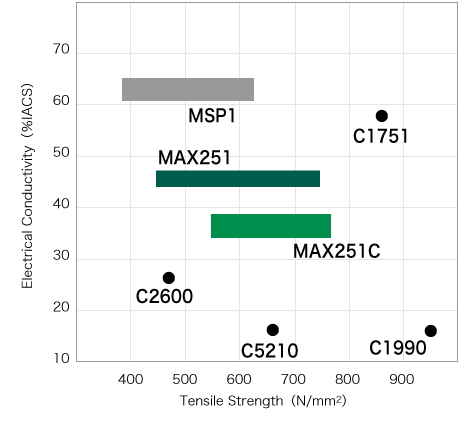

MAX251 has excellent properties of erectrical conductivity, strength and workability, and also that can be used as an altanative to phosphor bronze.

MAX251 has high electrical conductivity than other MAX sereis.

MAX251 is one of corson alloys developed by Mitsubishi Material.

It has high electrical conductivity than other MAX sereis and middle range strength.

Small terminals, connectors, relays, sockets

(Weight %)

| Ni | Si | Sn | Zn | Cu |

|---|---|---|---|---|

| 2 | 0.5 | 0.5 | 1 | Rem. |

The physical properties of MAX251 are as follows.

| Property | Representative Value |

|---|---|

| Specific Gravity (293K) | 8.9 |

| Coefficient of Thermal Expansion (×10-6/K:293~573K) | 17.1 |

| Thermal Conductivity (W/(m・K):293K) |

194 |

| Volume Resistivity (μΩm:293K) |

0.038 |

| Electrical Conductivity (%IACS:293K) | 46 |

| Modulus of Elasticity (kN/mm2 : 293K) |

130 |

| Temper | |||||

|---|---|---|---|---|---|

| 1/2H | H | EH | SH | ESH | |

| Tensile Strength (N/mm2) |

450~550 | 500~600 | 540~640 | 600~700 | 700 min. |

| 0.2% Yield Strength (N/mm2) |

390~520 | 440~580 | 480~630 | 540~690 | 650 min. |

| Elongation (%) |

8 min. | 6 min. | 4 min. | 2 min. | - |

| Elastic Limit Kb0.1※1[kN/mm2] |

- | - | (400 min.) | (440 min.) | (470 min.) |

| Vickers Hardness※2 (HV) |

(125~185) | (140~200) | (150~215) | (165~230) | (200 min.) |

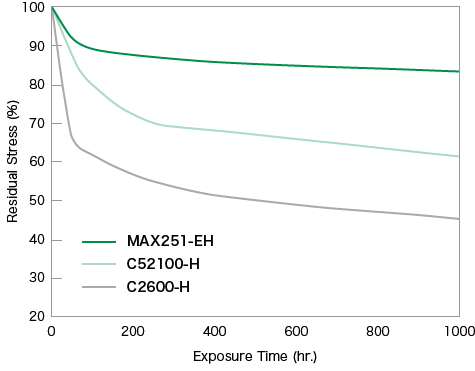

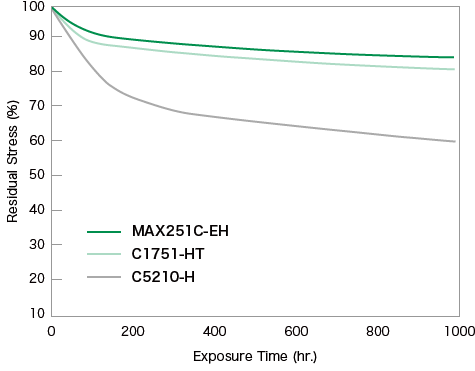

MAX251 has excellent stress relaxation resistance than phosphor bronze(C5210) and brass (C2600).

Exposure temperature: 150℃

Sampling direction: Parallel to the rolling direction

Bending stress: 80% of 0.2% yield strength

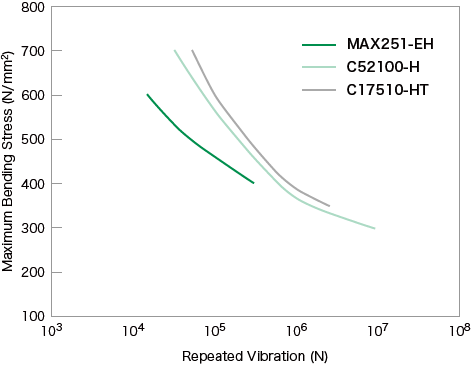

The fatigue characteristics of the MAX 251 meet the level required for springs and terminals.

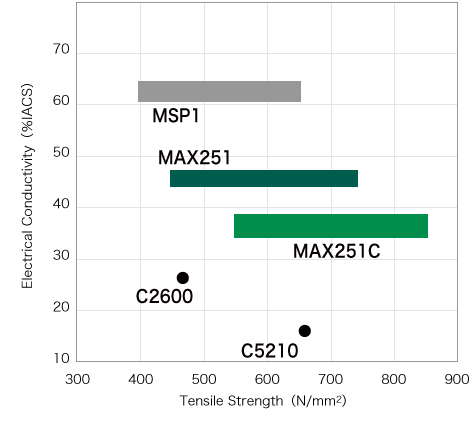

The MAX 251C is a high-strength copper alloy which is further improved in properties by utilizing special heat treatment during the manufacturing process, not only improved in the strength but also reduced the anisotropy of the mechanical properties, and has the optimized balance between the strength and the bending workability. It has been developed for various applications due to its good workability.

The MAX 251C is a Corson alloy that has the improved strength and bending workability compared with conventional products through its own manufacturing process. It realizes further miniaturization of parts by obtaining the balance between the strength and the bending workability which is better than that of MAX 251. It is also possible to switch titanium copper with beryllium copper.

Small male and female terminals for Automotive, LED lamp socket, fuse terminal, small switch, consumer terminal · connector

The chemical components of MAX251C are as follows.

(Weight %)

| Ni | Si | Sn | Zn | Cu |

|---|---|---|---|---|

| 2 | 0.5 | 0.5 | 1 | Rem. |

The physical properties of MAX251C are as follows.

| Property | Representative Value |

|---|---|

| Specific Gravity(293K) | 8.9 |

| Coefficient of Thermal Expansion (×10-6/K:293~573K) |

17.1 |

| Thermal Conductivity (W/(m・K):293K) |

160 |

| Volume Resistivity (μΩm:293K) |

0.047 |

| Electrical Conductivity (%IACS:293K) |

37 |

| Modulus of Elasticity (kN/mm2: 293K) |

130 |

The mechanical properties of MAX251C are as follows.

| Temper | Typical values | |||||

|---|---|---|---|---|---|---|

| 1/2H | H | EH | 1/2H | H | EH | |

| Tensile Strength (N/mm2) |

540~640 | 600~700 | 640~740 | 626 | 675 | 717 |

| 0.2% Yield Strength (N/mm2) |

480~630 | 540~690 | 580~735 | 554 | 584 | 663 |

| Elongation (%) |

8 | 5 | 3 | 17.3 | 14.8 | 11.4 |

| Elastic Limit Kb0.1※1[kN/mm2] |

- | - | - | (477) | (529) | (562) |

| Vickers Hardness※2 (HV) |

(150~215) | (165~230) | (180~240) | (187) | (199) | (211) |

| Electrical Conductivity [%IACS] |

33 min. | 40 | 38 | 38 | ||

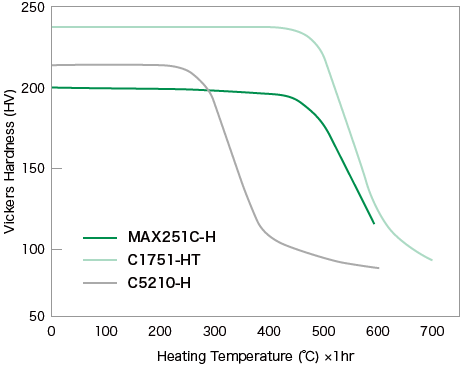

The MAX251C has sufficient heat resistance as a terminal material to be used at high temperatures.

It shows that it has stress relaxation properties equalt to or greater than beryllium copper and phosphor bronze for spring.

Exposure temperature: 150℃

Sampling direction: Parallel to the rolling direction

Bending stress: 80% of 0.2% yield strength

The bending workability of the MAX251C is as follows.

While having high strength, it also has excellent bending workability. This can contribute to miniaturization and improvement of reliability of parts.

| Temper | Sampling Direction | Bending Inside Radius (mm) R | Evaluation R/t | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (to the rolling direction) | 0.0 | 0.1 | 0.125 | 0.15 | 0.2 | 0.25 | 0.4 | 0.6 | 0.8 | 1.0 | ||

| 1/2H | 0°:(Good way) | △ | ○ | ○ | ○ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | 0.0 |

| 90°:(Bad way) | ○ | ○ | ○ | ○ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | 0.0 | |

| H | 0°:(Good way) | △ | △ | △ | △ | △ | △ | ○ | ◎ | ◎ | ◎ | 0.0 |

| 90°:(Bad way) | ○ | ○ | ○ | ○ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | 0.0 | |

| EH | 0°:(Good way) | ▲ | ▲ | ▲ | △ | △ | △ | △ | ○ | ○ | ○ | 0.6 |

| 90°:(Bad way) | ▲ | ▲ | △ | ○ | ○ | ○ | ○ | ◎ | ◎ | ◎ | 0.5 | |

TEL:+81-3-5252-4956

TEL:+81-72-233-9240