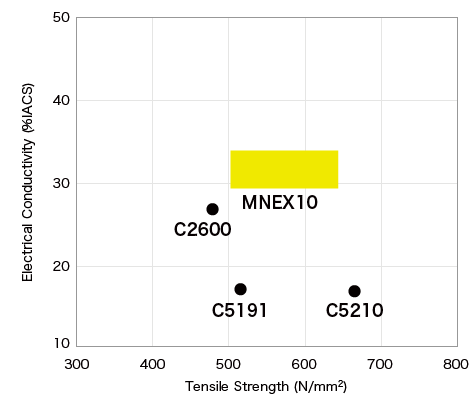

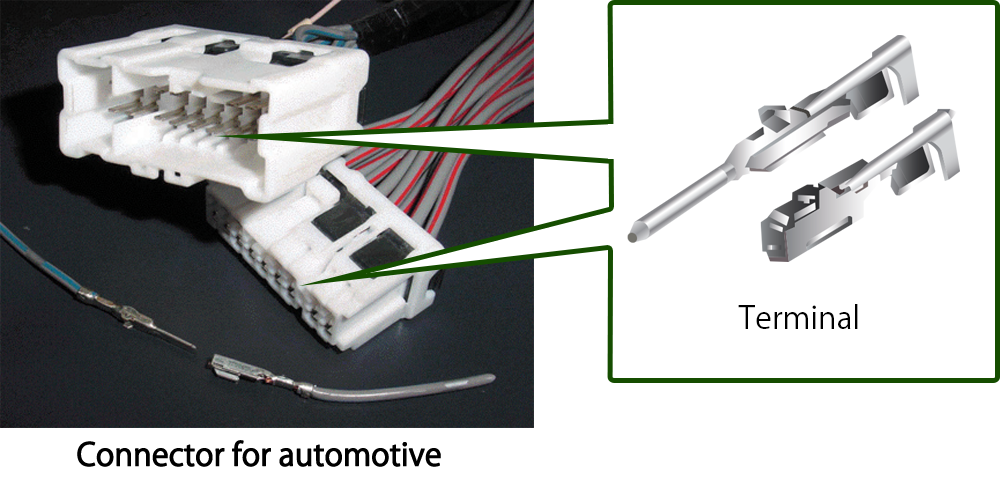

Next-generation Cost-Effective copper alloy. The world's first Cu-Zn based alloy contributing to the excellent terminal performance and low cost. It is an innovative material that overcomes the deterioration of the spring properties under the high temperature or corrosive environment which was a weak point of the conventional Cu-Zn system. It contributes to the demonstration of the excellent terminal performance and low cost.

A copper alloy for automotive general purpose terminals. When it is excellent in the strength and the bending workability, it also has stress relaxation resistance characteristics. It has characteristics that can be applied to various applications.

In-vehicle terminals, consumer terminals, bus bars, spring materials, press-fit terminals

(Weight %)

| Zn | Ni | Sn | Fe | P | Cu |

|---|---|---|---|---|---|

| 10 | 0.6 | 0.6 | 0.01 | 0.04 | Rem. |

The physical properties of MNEX 10 are as follows.

| Property | Representative Value |

|---|---|

| Specific Gravity (297K) |

8.8 |

| Coefficient of Thermal Expansion (×10 |

18.4 |

| Thermal Conductivity (W/(m・K) : 293 K) |

138 |

| Volume Resistivity (µΩm : 293 K) |

0.057 |

| Electrical Conductivity (%IACS : 293 K) |

30 |

| Modulus of Elasticity (kN/mm2: 293 K) |

123 |

The mechanical properties of MNEX 10 are as follows.

| Temper | Typical Values | |||

|---|---|---|---|---|

| H | EH | H | EH | |

| Tensile Strength (N/mm2) |

500〜600 | 550〜650 | 541 | 580 |

| 0.2% Yield Strength (N/mm2) |

450〜550 | 500〜600 | 508 | 546 |

| Elongation (%) |

7Min. | 3Min. | 11 | 10 |

| Elastic Limit※1 Kb0.1(N/mm2) |

(350Min.) | (400Min.) | (493) | (589) |

| Vickers Hardness※2 (HV) |

(150〜190) | (160〜210) | (168) | (182) |

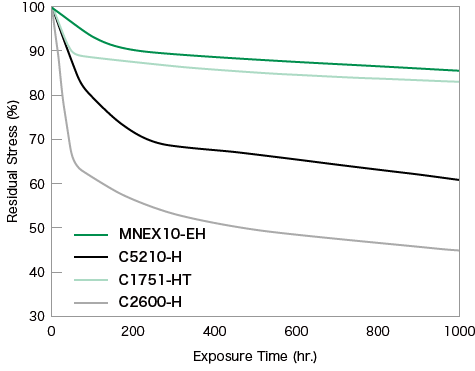

The residual stress ratio of MNEX 10 is shown on the right. MNEX 10 has excellent stress relaxation characteristics among copper alloys and has extremely high reliability as a terminal material.

Exposure temperature: 150℃ Good Way (bending axis perpendicular to rolling direction)

Bending stress: 0.2% of 80% proof stress

The bending workability of MNEX 10 is as follows.

| Temper | Sampling Direction (to the rolling direction) |

Bending Inside Radius (mm) R | Evaluation | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.0 | 0.1 | 0.125 | 0.15 | 0.2 | 0.25 | 0.40 | R/t | ||

| H | 0°:(Good Way) | △ | ○ | ○ | ○ | ○ | ◎ | ◎ | 0.0 |

| 90°:(Bad way) | △ | ○ | ○ | ○ | ○ | ◎ | ◎ | 0.0 | |

| EH | 0°:(Good Way) | △ | △ | △ | ○ | ○ | ○ | ◎ | 0.0 |

| 90°:(Bad way) | ▲ | ▲ | △ | △ | △ | △ | ○ | 0.5 | |

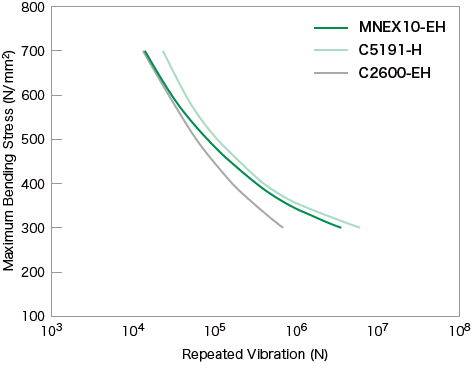

MNEX 10 has equivalent or higher fatigue characteristics than phosphor bronze for spring and brass.

TEL:+81-3-5252-4956

TEL:+81-72-233-9240