The nickel silver has a silver-white copper alloy with a beautiful color tone. Thanks to its excellence in the mechanical properties and discoloration resistance, it has been used for a variety of items such as decoration, tableware, and musical instruments from the past.

Now, it is used for electronic components such as quartz oscillator cases, switch for measuring instruments, and connectors.

Since nickel silver may become more preferable material with its excellence in characteristics in the future, as platingless copper alloy products prevails in line with the rise of social issues like environmental problems.

We manufactures the nickel silver products by hot rolling process so that we guarantee high quality of our products.

Types and representative compositions of the nickel silver are as follows.

Chemical composition

(Weight %)

| Alloy | Cu | Ni | Zn |

|---|---|---|---|

| NS2 | 64 | 17.5 | Rem. |

| NS3 | 62 | 14 | Rem. |

| NS4 | 65 | 10 | Rem. |

| NS5 | 69 | 12 | Rem. |

| NS7 | 65 | 15 | Rem. |

| NSS | 56 | 17.5 | Rem. |

| NSL | 70 | 6 | Rem. |

There are no big differences in the density and other physical properties of the nickel silver alloy.

The modulus of longitudinal elasticity of the nickel silver alloy is superior to C2600 (105 kN / mm2), which is very advantageous in terms of mechanical properties.

| Property | NS2 | NS3 | NS4 | NS5 | NS7 | NSS | NSL |

|---|---|---|---|---|---|---|---|

| Specific Gravity(293K) | 8.7 | 8.7 | 8.7 | 8.7 | 8.7 | 8.7 | 8.6 |

| Melting Point(℃) | 1110 | 1040 | 1020 | 1070 | 1075 | 1055 | 1000 |

| Electrical Conductivity (%IACS:293K) |

6 | 8 | 9 | 8 | 7 | 6 | 12.5 |

| Thermal Conductivity (W/(m・k):297K) |

93 | 105 | 128 | 105 | 105 | 93 | 163 |

| Coefficient of liner expansion (×10-6/K : 293~573K) |

16.2 | 16.2 | 16.4 | 16.2 | 16.2 | 16.2 | 17 |

| Modulus of Elasticity (kN/mm2:293K) |

130 | 126 | 123 | 125 | 127 | 130 | 121 |

The tensile strength of NS 7 is higher about 80 N/mm2than that of C2600.

| Temper | G.S. µm |

Tensile Strength N/mm2 |

Yield strength N/mm2 |

Elongation % |

Hardness HV1 |

Erichsen Value mm |

|---|---|---|---|---|---|---|

| O | 10 | 440 | 230 | 34.0 | 115 | 11.0 |

| 20 | 420 | 175 | 40.0 | 105 | 12.0 | |

| 35 | 385 | 140 | 43.0 | 85 | 12.5 | |

| 1/4H | 12 | 450 | 230 | 33.0 | 120 | 11.0 |

| 1/2H | - | 500 | 450 | 14.0 | 160 | - |

| H | - | 570 | 550 | 6.0 | 175 | - |

| EH | - | 610 | 600 | 2.0 | 195 | - |

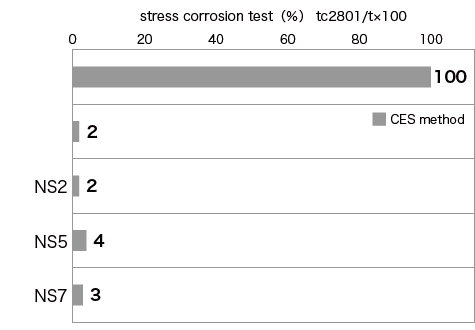

The criteria of CES are determined based on that cracking does not occur with exposure for 72 hours.

The stress corrosion cracking resistance of various types of nickel silver sufficiently satisiesy the criteria of CES and is further superior to C2600.

NS 7 shows good bending characteristics, 180°of tight bending is performed with half H material, and the cracking does not occur with W bending of R/t =0.5 with H material.

| Temper | good way | bad way | ||||

|---|---|---|---|---|---|---|

| adhension | t/2 | t | adhension | t/2 | t | |

| O | ○ | ○ | ○ | ○ | ○ | ○ |

| ○ | ○ | ○ | ○ | ○ | ○ | |

| ○ | ○ | ○ | ○ | ○ | ○ | |

| 1/4H | ○ | ○ | ○ | ○ | ○ | ○ |

| 1/2H | ○ | ○ | ○ | ○ | ○ | ○ |

| H | △ | ○ | ○ | △ | ○ | ○ |

| EH | △ | ○ | ○ | × | ○ | ○ |

TEL:+81-72-233-9240