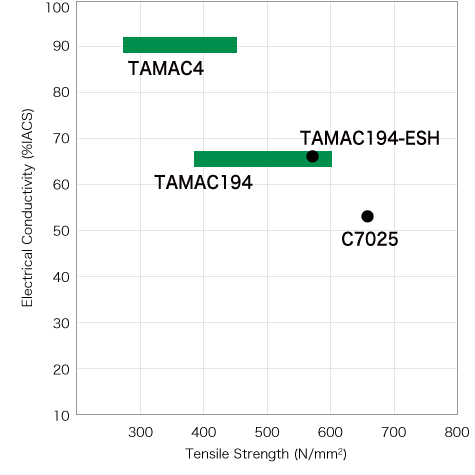

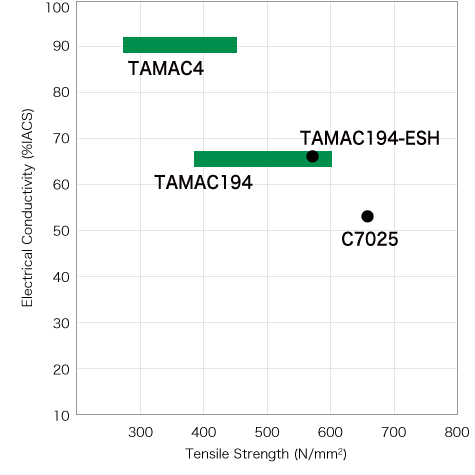

TAMAC series are applied to electronic parts, have excellent characteristics as lead frame materials for semiconductors, and furthermore, have been improved to a high added value copper alloy in response to user needs.

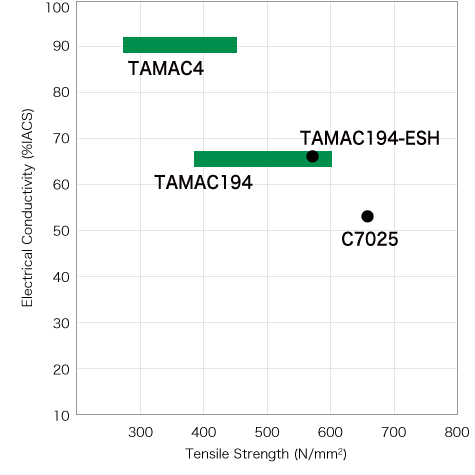

The TAMAC series are Cu-Fe-P type copper alloys and have been used for electronic materials for many years. Mitsubishi Material have promoted alloy development and prepared a wide variety of variations in order to realize high conductivity (for power semiconductor and bar applications) and high strength (lead frame, clip terminal, and the like) with respect to the required characteristics of electronic parts.

TAMAC 194 is a representative copper alloy that is used for IC lead frames, bus bars, and civil spring parts in terms of the excellent balance between the strength and the conductivity, the heat resistance, the press workability, and the bending workability.

TAMAC 194 is widely used for the lead frames, and has ESH with improved high strength and elongation, which is obtained by arranging the manufacturing method so as to be compatible with highly integrated and advanced IC. The quality obtained by precision rolling technology boasts the world's top class.

lead frame for IC(LED,In-vehicle microcomputer), bus bars, fuse terminals and the like

The chemical components of TAMAC194 are as follows.

(Weight %)

| Fe | Zn | P | Cu |

|---|---|---|---|

| 2.3 | 0.12 | 0.03 | Rem. |

The physical properties of TAMAC194 are as follows.

(Weight %)

| Property | Representative Value |

|---|---|

| Specific Gravity (293K) | 8.8 |

| Coefficient of Thermal Expansion (×10-6/K:293~573K) |

17.6 |

| Thermal Conductivity (W/(m・K):293K) |

262 |

| Volume Resistivity (μΩm:293K) |

0.026 |

| Electrical Conductivity (%IACS:293K) |

66 |

| Modulus of Elasticity (kN/mm2:293K) |

121 |

TAMAC 4 is widely used for the power semiconductor lead frames due to its high conductivity and heat dissipation properties, and is highly reliable as a general copper alloy for high current applications such as bus bar material and fixing piece for relays.

The electrical conductivity of TAMAC4 is as high as 90%IACS,which is equivalent to one of pure copper. TAMAC4 has been widely applied for the whole electrical parts,power semiconductors and busbars which require high current and high voltage.

Power IC lead frame, bus bar material, fixing piece for relay

The chemical components of TAMAC4 are as follows.

(Weight %)

| Fe | P | Cu |

|---|---|---|

| 0.1 | 0.03 | Rem. |

The physical properties of TAMAC4 are as follows.

| Property | Representative Value |

|---|---|

| Specific Gravity (293K) | 8.8 |

| Coefficient of Thermal Expansion (×10-6/K:293~573K) |

17.6 |

| Thermal Conductivity (W/(m・K):293K) |

347 |

| Volume Resistivity (μΩm:293K) |

0.0192 |

| Electrical Conductivity (%IACS:293K) |

90 |

| Modulus of Elasticity(kN/mm2:293K) | 118 |

| Temper | ||||

|---|---|---|---|---|

| 1/4H | 1/2H | H | EH | |

| Tensile Strength (N/mm2) |

275~355 | 295~375 | 335~410 | 375min. |

| Elongation (%) |

20min. | 10min. | 5min. | - |

| Vickers Hardness* (HV) |

90~115 | 100~125 | 110~135 | 115min. |

The bending workability of TAMAC4 is as follows.

| Temper | Sampling Direction (to the rolling direction) |

Bending Inside Radius (mm) R | Evaluation | |||||

|---|---|---|---|---|---|---|---|---|

| 0.0 | 0.125 | 0.2 | 0.25 | 0.4 | 0.6 | R/t | ||

| 1/2H (Thickness: 0.40mm) |

0°:(Good Way) | △ | △ | △ | ○ | ○ | ○ | 0.0 |

| 90°:(Bad way) | △ | △ | △ | △ | ○ | ○ | 0.0 | |

| H (Thickness: 0.25mm) |

0°:(Good Way) | ▲ | △ | △ | ○ | ○ | ○ | 0.5 |

| 90°:(Bad way) | ▲ | △ | △ | ○ | ○ | ○ | 0.5 | |

TEL:+81-3-5252-4981