It is a special high-strength brass bar with improved strength and wear resistance by solid solution strengthening and precipitation strengthening of Mn-Si intermetallic compounds.

The demand for high-strength, wear-resistant copper alloys is growing as the speed and performance of working parts in machinery and equipment increases. UH 13's high strength and machinability make it a cost-effective alternative to stainless steel and bronze for components.

UH13 has high-strength and excellent wear resistance.

It is suitably used for sliding parts such as bearings and gears such as a cylinder block, a shoe, a liner, a thrust metal, a screw nut, a hub wheel, a bush, and pinion gear.

It shows chemical components of UH13.

| Cu | Al | Zn | Pb | Mn | Si | |

|---|---|---|---|---|---|---|

| UH13 | 62.0 | 3.0 | Rem. | 0.3 | 3.0 | 1.0 |

It shows physical properties of UH13.

| Property | Representative Value |

|---|---|

| UH13 | |

| Specific Gravity (293K) | 7.9 |

| Coefficient of Thermal Expansion (×10-6/K:293~573K) |

20 |

| Thermal Conductivity (W/(m・K):293K) |

101 |

| Electrical Conductivity (%IACS:293K) |

23 |

It shows chemical components of UH13.

| Property | Representative Value |

|---|---|

| UH13 | |

| Tensile Strength (N/mm2) |

730 |

| 0.2% Yield Strength (N/mm2) |

500 |

| Elongation (%) |

10 |

| HV | 230 |

| HRB | 98 |

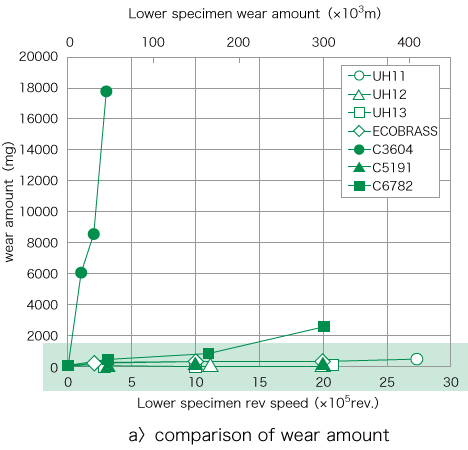

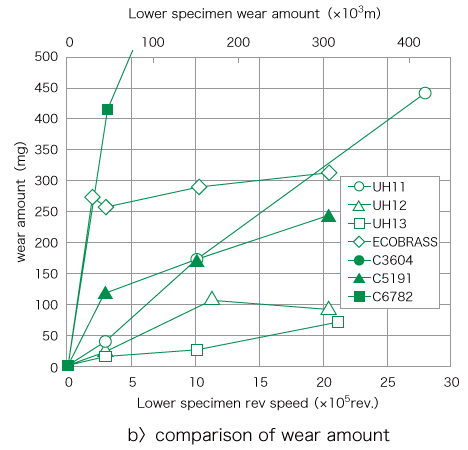

When referring to the wear test results in the Amsler type abrasion test (under lubrication), the reduced wear amount of UH13 is equal to or less than 1/2 of C5191, and it is possible to confirm the excellent wear resistance.

TEL:+81-3-5252-5202

TEL:+81-6-6355-5101