If brass alloy contacts to water or seawater, zinc may salectively elutes from the brass allow surface, which is called "dezincification".

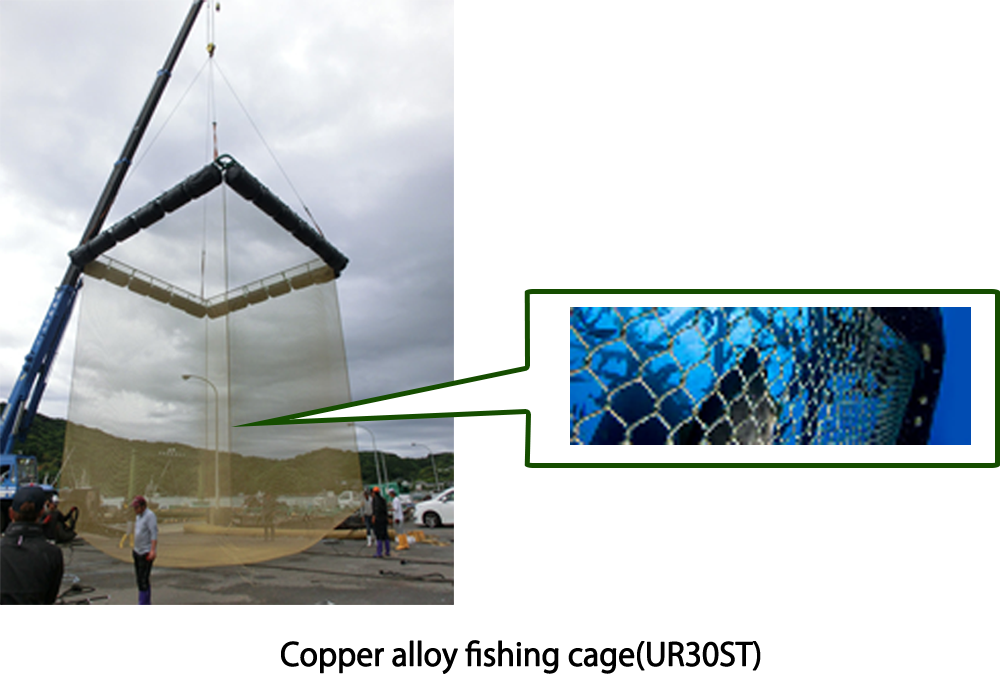

The UR30ST is copper alloy materials with excellent dezincification corrosion resistance. We can provide optimum materials accordingly to the application. UR30ST is suitable alloy especially for the wire of Aquaculture.

The chemical components of UR30ST is as follows.

| Cu | Pb | Fe | Sn | Ni | Al | Zn | |

|---|---|---|---|---|---|---|---|

| UR30ST | 67.0 | 0.7 | 0.6 | Rem. |

The physical properties of UR30ST is as follows.

| Property | Representative Value |

|---|---|

| UR30ST | |

| Specific Gravity (293K) | 8.5 |

| coeffcient of thermal Expansion (×10-6/K:293~573K) |

21 |

| electrical conductivity (%IACS:293K) |

20 |

| Modulus of Elasticity (kN/mm2:293K) |

103 |

The mechanical properties of UR30ST is as follows.

| alloy | UR30ST |

|---|---|

| Shape | wire |

| size | Ø4 |

| Temper | 1/4H |

| Tensile Strength (N/mm2) |

420 |

| Yield Strength (N/mm2) |

- |

| Elongetion (%) |

23 |

| Hardness (HRB) |

52 |

It shows corrosion resistance of UR30ST.

UR30ST have excellent dezincification corrosion resistance.

| Alloy | Ø | ISO 6509 test | JBMA T-303 test | |||

|---|---|---|---|---|---|---|

| maximum corrosion depth (μm) |

average corrosion (μm) |

corrosion form | maximum corrosion depth (μm) |

evaluation | ||

| UR30ST | Ø4 | <10 | <10 | no dezincification | 60 | type Ⅰ |

It satisfies the stress corrosion cracking test by JIS method and ASTM method (both conducted in ammonia atmosphere).

| JIS | ASTM | |

|---|---|---|

| UR30ST | ○ | ○ |

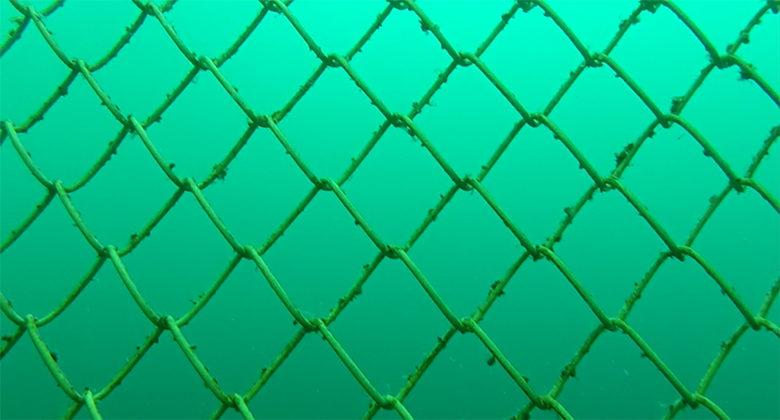

UR30ST has excellent antifouling properties (properties that prevent the adherence of marine organisms such as algae and shellfish), and it is used as a wire of crawls for sea surface culturing.

Galvanized steel wire crawl (4 months passed after installation)

UR30ST crawl (2 years passed after installation)

TEL:+81-3-5252-5202

TEL:+81-6-6355-5101