WNS7 has gained popularity from users as well as achieved high market share especially in keys of cars and houses, thanksto its white color tone and excellent characteristics.

The chemical components of WNS7 are as follows.

| Cu | Ni | Mn | Zn |

|---|---|---|---|

| 49 | 9 | 6 | Rem. |

The physical properties of WNS7 are as follows.

| Property | ||||

|---|---|---|---|---|

| Property | WNS7 | C7941 Free-cutting nickel silver |

C6782 High strength brass |

C3771 Forging brass |

| Specific Gravity (293K) | 8.3 | 8.8 | 8.3 | 8.45 |

| Coefficient of Thermal Expansion (×10-6/K:293~573K) |

17 | 17 | 19 | 21 |

| Electrical Conductivity (%IACS:293K) |

4.4 | 5.5 | 25 | 27 |

| Modulus of Elasticity (kN/mm2: 293K) |

114 | 125 | 98 | 98 |

It shows the mechanical properties of WNS7.

WNS7 has strength comparable to nickel silver for spring.

| Temper | Tensile Strength (N/mm2) |

Elongation (%) |

Yield strength (N/mm2) |

Hardness* | Fatigue Strength N=107 N/mm2 |

|---|---|---|---|---|---|

| O | 470 | 63 | 220 | (103) | 190 |

| 1/4H | 510 | 47 | 340 | (140) | 220 |

| 1/2H | 570 | 33 | 440 | (165) | 230 |

| H | 630 | 20 | 540 | (190) | 240 |

| EH | 740 | 9 | 650 | (215) | 250 |

WNS7 shows corrosion resistance equivalent to that of two types of nickel silver.

Comparison of corrosion weight losses of WNS7 and two types of the nickel silver when being immersed in various solutions

| Item | HCl* | H2SO4* | Artificial sweat * | Soy sauce | Vinegar | Detergent | Gasoline |

|---|---|---|---|---|---|---|---|

| WNS7 | 230 | 79 | 71 | 8 | 152 | 7 | 0.5 |

| C7521 | 570 | 78 | 86 | 9 | 300 | 3 | 0.5 |

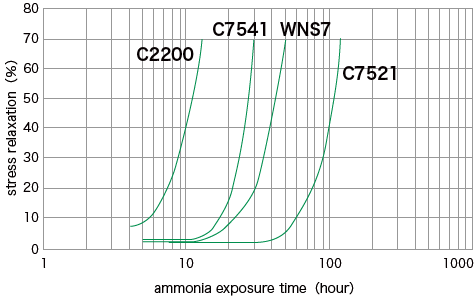

Generally, it is said that it has small stress corrosion cracking susceptibility, is superior to stress corrosion cracking resistance than C2200 (trunk) with proven performance, and is slightly inferior to C7521 (two types of the nickel silver).

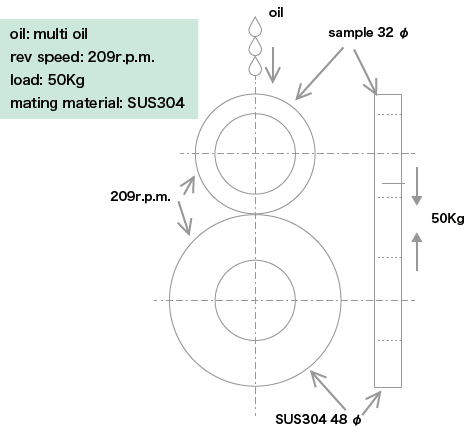

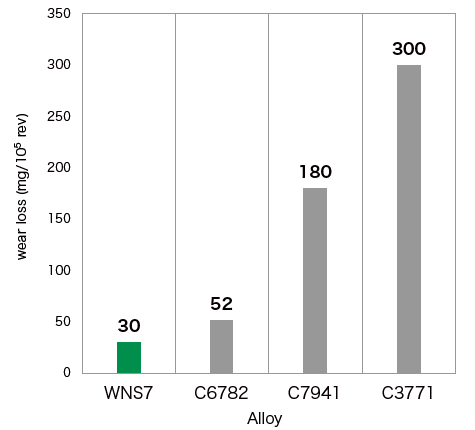

A load of 50 kgf was applied to the test piece by using the Amsler type wear test as shown in the figure below, and then wear tests for rolling and sliding were conducted. The results are shown in the figure below. WNS7 exhibits better wear resistance than that of C6782, C7941, and C3771, and does not adversely affect the wear amount of SUS 304 which is the mating material.

TEL:+81-72-233-9240