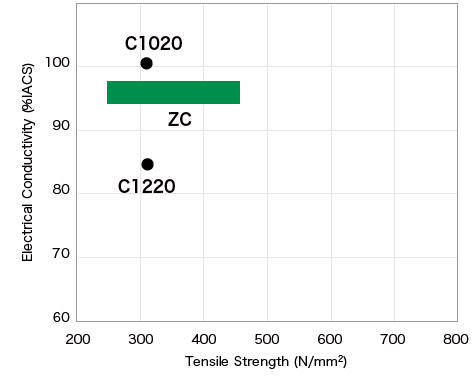

Highly heat resistant copper alloy for lead frame with high conductivity of oxygen-free copper class

It is used for power semiconductors such as olead frames and heat sinks with copper alloys with the same conductivity as that of copper and excellent strength and heat resistance.

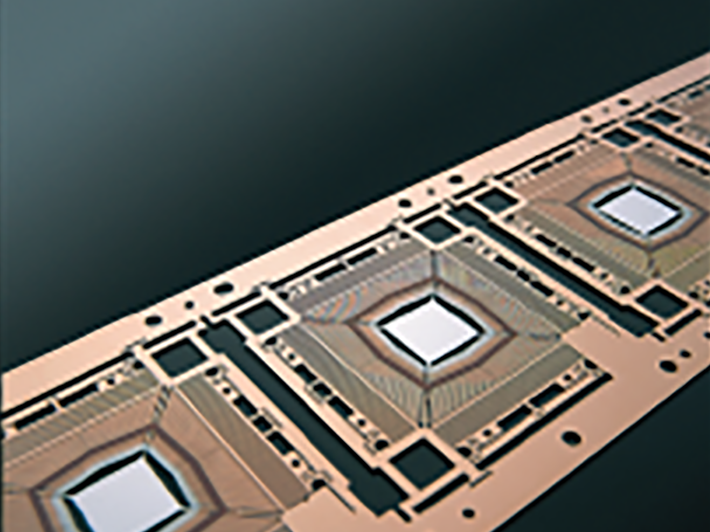

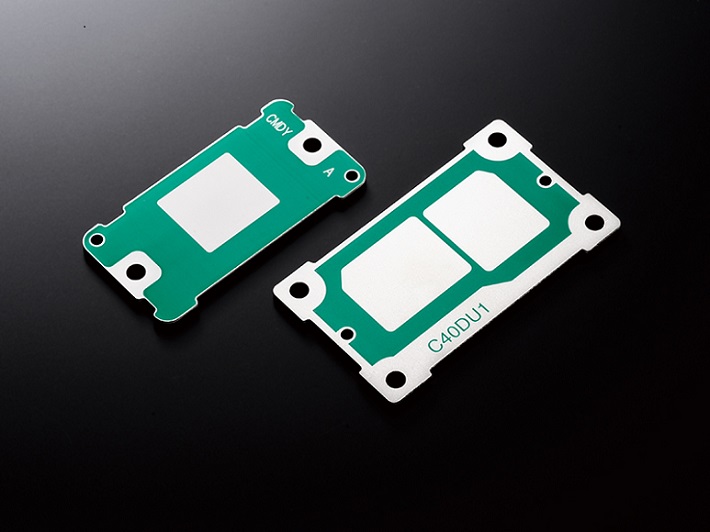

Heat sinks for various semiconductor package, lead frame for transistor, lead frame for IC, and the like

The chemical components of ZC are as follows.

(Weight %)

| Zr | Cu |

|---|---|

| 0.02 | Rem. |

The physical properties of ZC are as follows.

| Property | Representative Value |

|---|---|

| Specific Gravity (293K) | 8.9 |

| Coefficient of Thermal Expansion (×10-6/K:293~573K) |

17.7 |

| Thermal Conductivity (W/(m・K):293K) |

373 |

| Volume Resistivity (μΩm:293K) |

0.018 |

| Electrical Conductivity (%IACS:293K) |

97 |

| Modulus of Elasticity (kN/mm2: 293K) |

121 |

Mechanical properties of ZC are as follows.

ZC has strength exceeding that of pure copper as required characteristic for lead frame application.

| Temper | ||||

|---|---|---|---|---|

| 1/2H | H | EH | SH | |

| Tensile Strength (N/mm2) |

245~295 | 295~355 | 355~410 | 410~470 |

| Elongation (%) |

6 | 4 | 2 | 2 |

| Vickers Hardness* (HV) |

(75~110) | (100~120) | (110~130) | (125min.) |

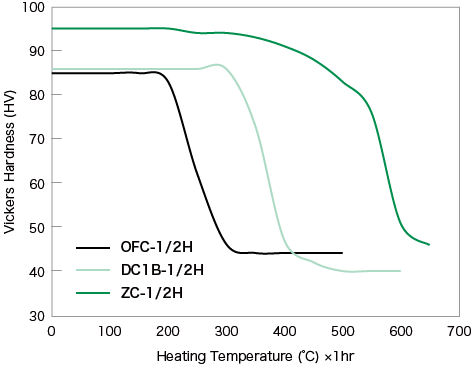

It corresponds to energization heat generation for high current semiconductor device applications and shows the heat resistance higher than pure copper.

TEL:+81-3-5252-4956

TEL:+81-72-233-9240

TEL:+81-3-5252-5202

TEL:+81-6-6355-5101