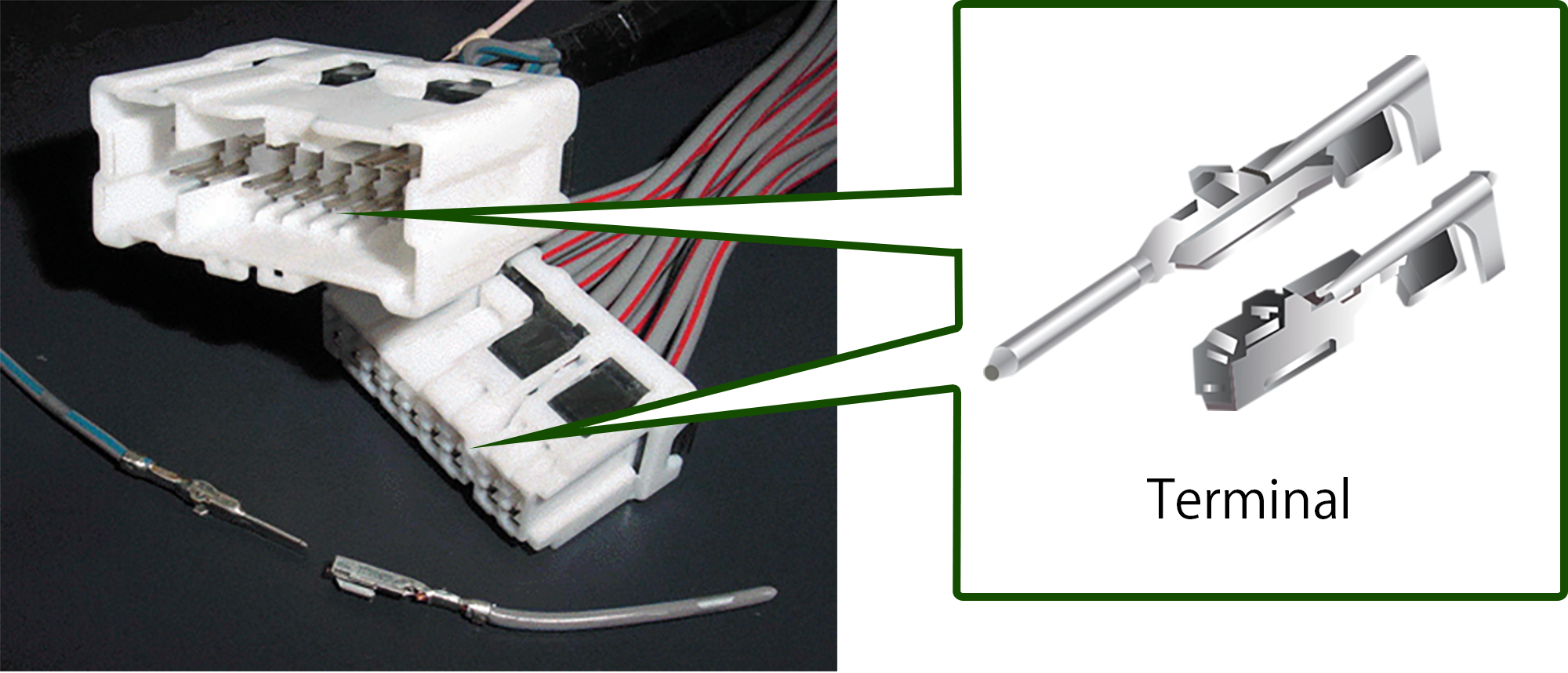

In comparison with conventional reflow Sn plating (conventional plating), PIC plated materials have a lower dynamic friction coefficient and superior electrical reliability. PIC plating is therefore expected to be deployed widely as a high-performance plating technology for next-generation terminals for automotive applications.

It is possible to pre-plate copper and copper alloy strips, and post-plating of pressed terminals.

※Plating on pressed terminals is carried out by licensed companies outside the MMC group.

Pre-plated material

Post-stamping plating

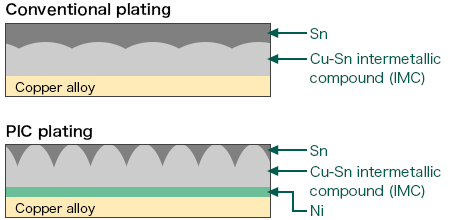

In PIC plating, the shape of the Cu-Sn compound formed at the interface between the copper alloy and the tin plating layer is precisely controlled so that a portion of it is exposed on the surface, with pure tin existing in the gap between them. This gives it a distinctive multi-phase structure.

Cross sections of conventional plating and PIC plating

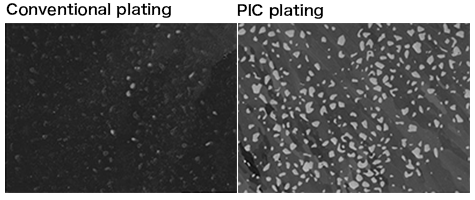

The white parts are Cu-Sn IMC

Surface images of conventional plating and PIC plating

(showing the extrusion of Cu-Sn IMC on the surface)

By combining PIC plating with various copper alloys and brass, the frictional resistance when inserting terminals can be significantly reduced, realizing high performance of automotive connector terminals.

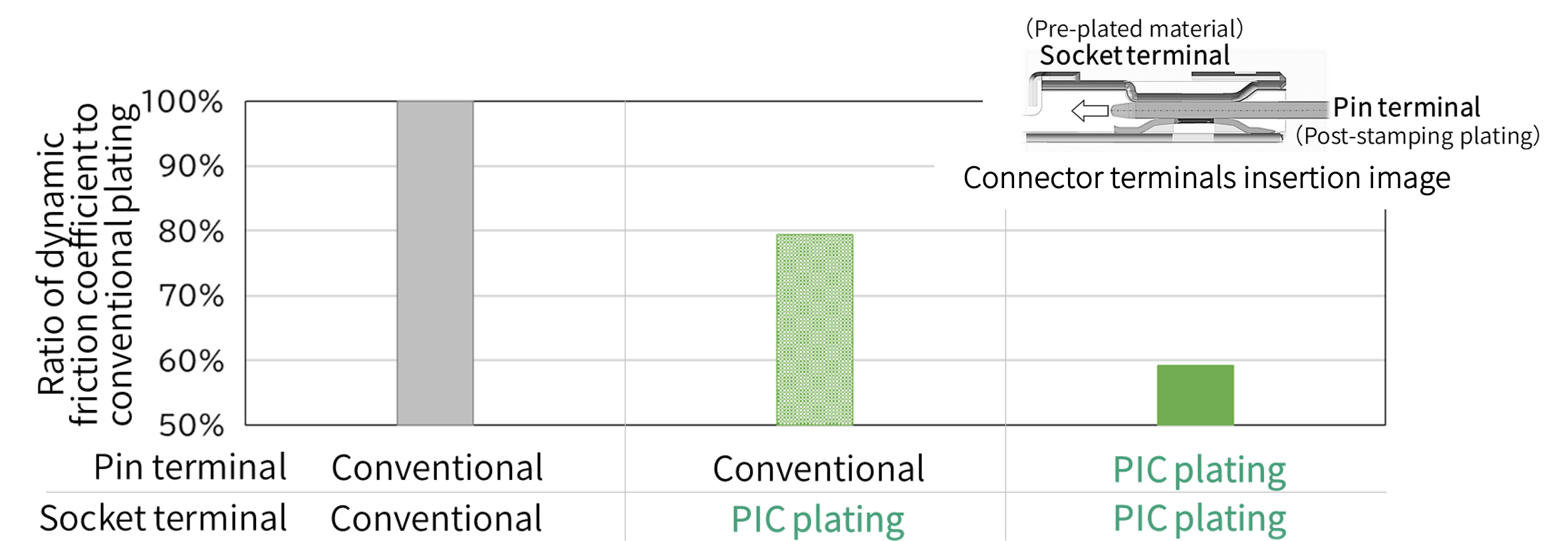

PIC plating can reduce friction even when used on either pin or socket terminals. By using it on both pins and sockets, the effect is even greater, reducing friction by about 40% compared to conventional plating.

It is particularly effective in reducing friction on small terminals with low contact pressure.

Dynamic friction coefficients for conventional plating and PIC plating