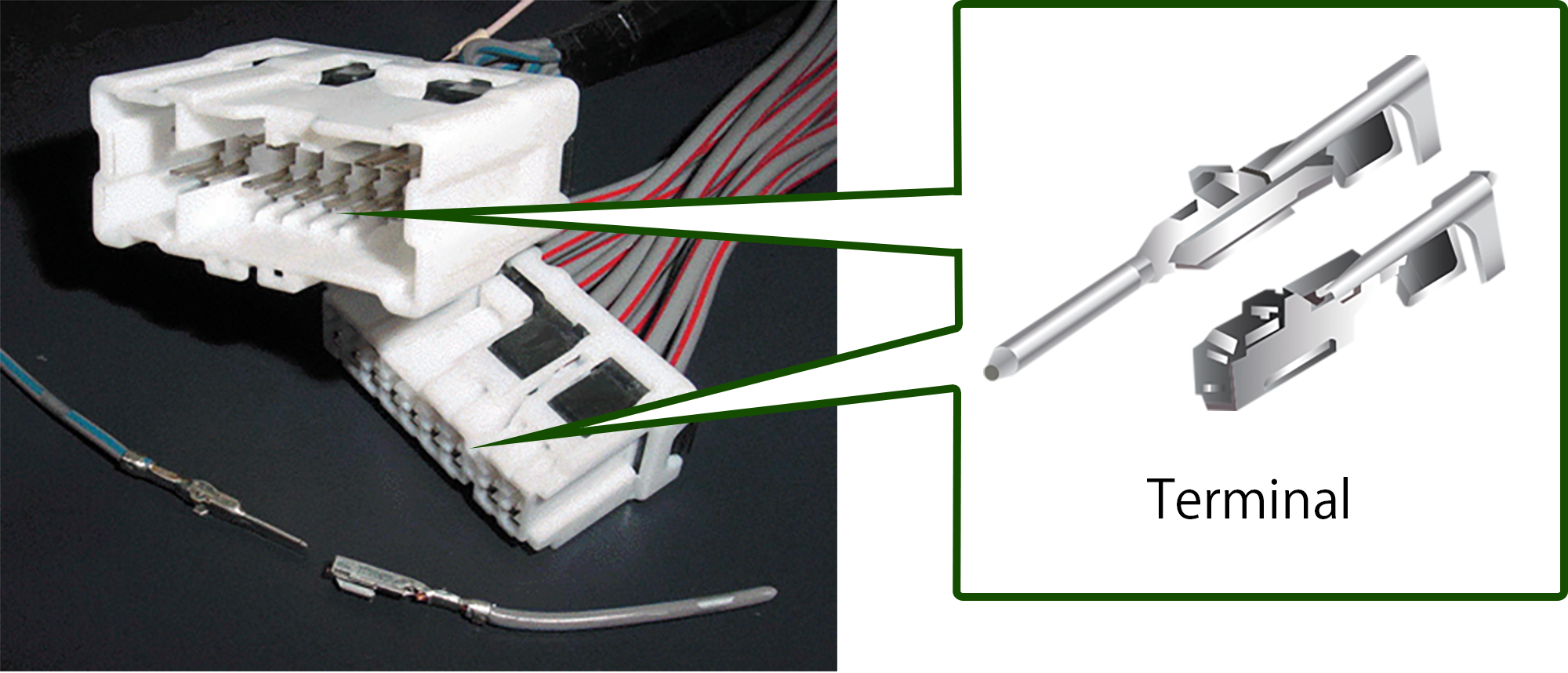

In comparison with conventional reflow Sn plating (conventional plating), PIC plated materials have a lower dynamic friction coefficient and superior electrical reliability. PIC plating is therefore expected to be deployed widely as a high-performance plating technology for next-generation terminals for automotive applications.

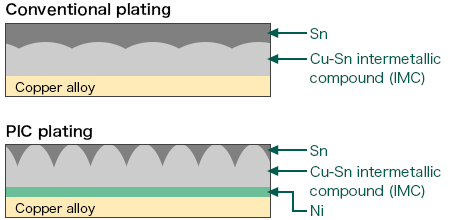

In PIC plating, the shape of the Cu-Sn intermetallic compound (IMC) formed at the boundary between the Cu alloy and Sn layers is precisely controlled to form column shapes that extrude evenly across the surface of the material, with pure Sn between the Cu-Sn IMC. This gives it a distinctive multi-phase structure.

Cross sections of conventional plating and PIC plating

The white parts are Cu-Sn IMC

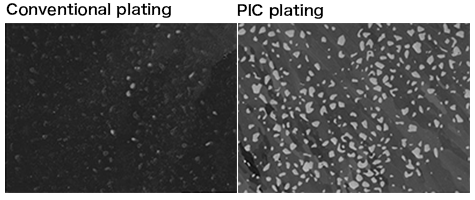

Surface images of conventional plating and PIC plating

(showing the extrusion of Cu-Sn IMC on the surface)

Combining PIC plating with various copper alloys and brass, etc., significantly reduces frictional resistance during terminal insertion and removal, enabling higher performance for terminals for automotive applications.

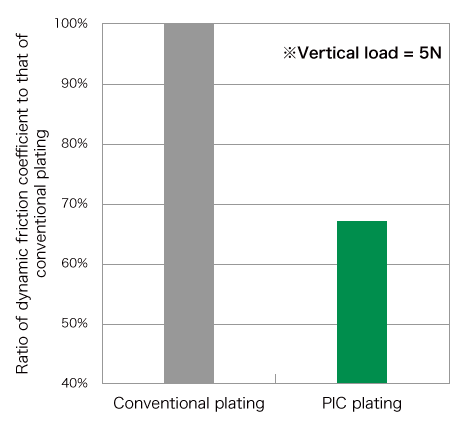

The dynamic friction coefficient for PIC plating is up to around 30% lower than conventional plating. In particular, it achieves greater reduction effects for small, compact-sized terminals which have low contact pressure.

Dynamic friction coefficients for conventional plating and PIC plating*

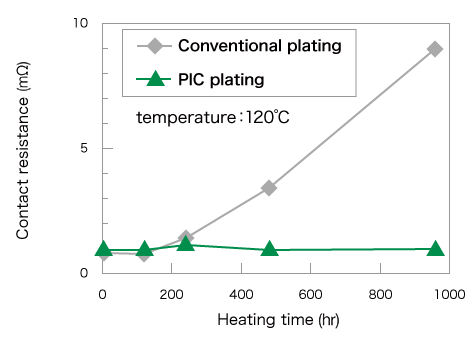

Because the initial contact resistance is still maintained even after sustained high temperature, PIC plating can maintain high electrical reliability even in the high-temperature conditions.

Contact resistance after sustaining a high temperature of 120℃

TEL:+81-3-5252-4956

TEL:+81-72-233-9240