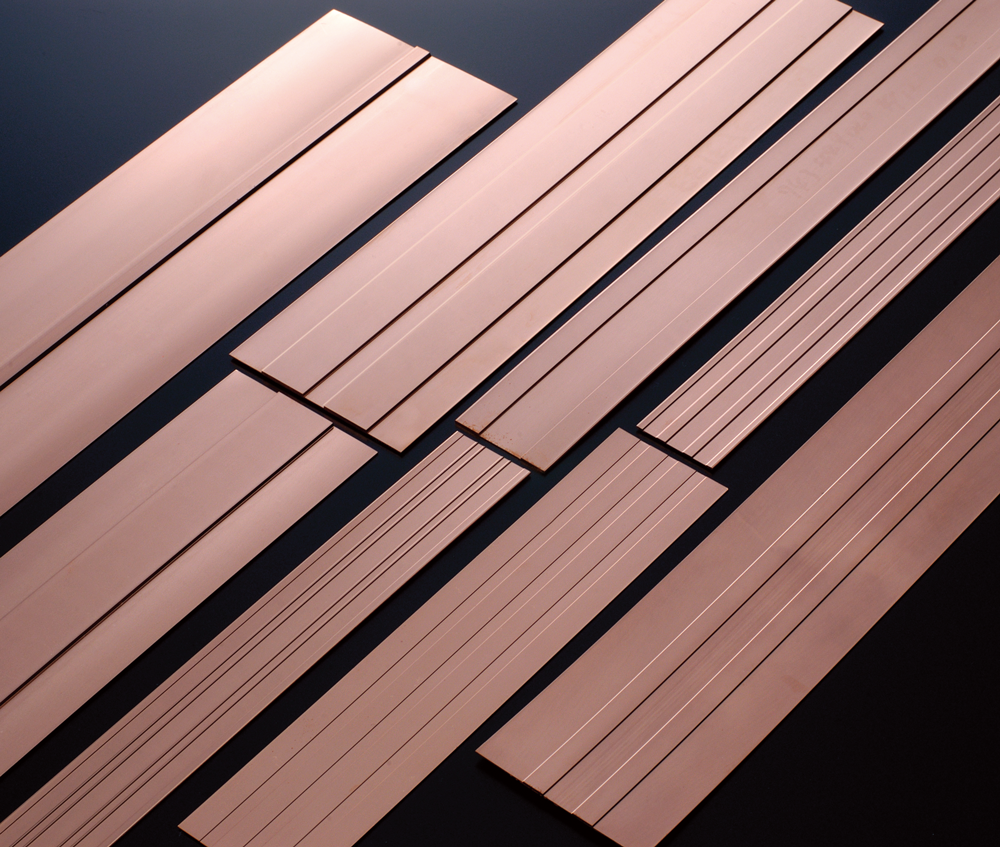

Multi-gauge strips are used as electronic materials and terminal materials like lead frame for power IC or high current terminal material because of their conductivity and heat dissipation properties of a thick plate portion as well as workability of a thin plate portion.

The more the demand for high conductivity increaes, the demand for this items as well will be expected to grow.

Lead frame for semiconductor (power transistor)

Applications for terminals and connectors

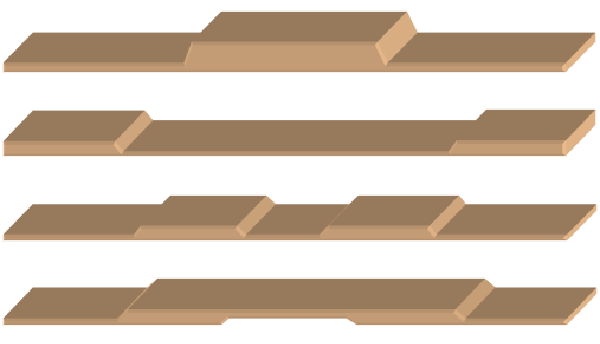

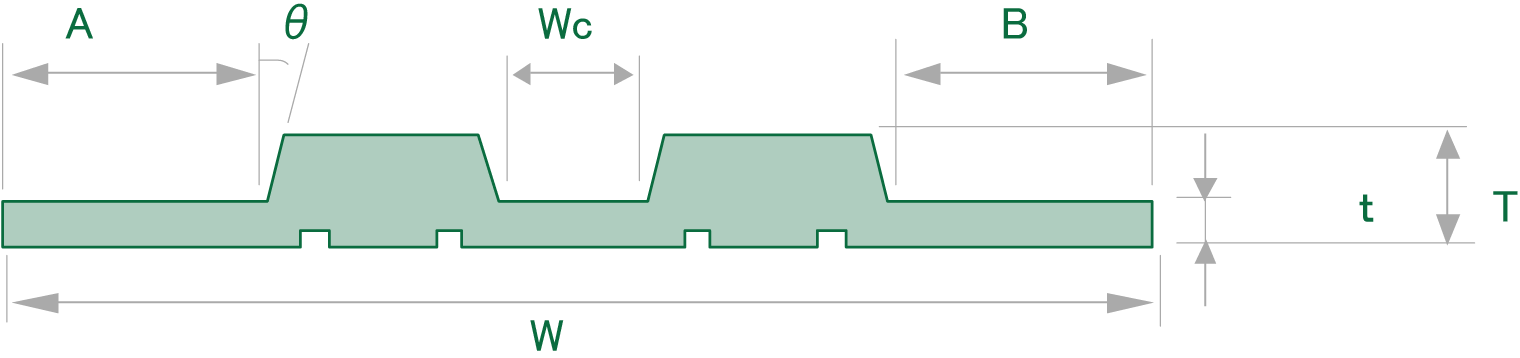

A stepped portion consisting of a thick portion and a thin section.

Lead frame for semiconductor (power transistor),terminal,connector and the like

| site | producable range | dimentional tolerance |

|---|---|---|

| T | ≤3.0mm | ±0.02 |

| t | 0.2mm≤ | ±0.02 |

| T/t | ≤5 | - |

| θ | 3°≤ | ±2 |

| Wc | ≤40mm | ±0.05 |

| W | ≤150mm | ±0.1 |

| |A-B| | - | ±0.2 |

| Mountain width | 0.8~42.0 | ±0.05 |

| Groove width | 0.3~0.51 | ±0.03 |

| Groove depth | 0.3~0.45 | ±0.03 |

| Warppage | ≤0.5mm | |

| Bending | ≤1.0/1000mm | |

| Burrs | ≤0.04mm | |

| Inner diameter of coil | Φ400mm | |

| Outer diameter of coil | ≤Φ1500mm | |

TEL:+81-3-5252-4981