Electrical conductivity , Strength and Stress relaxation resistance are high.

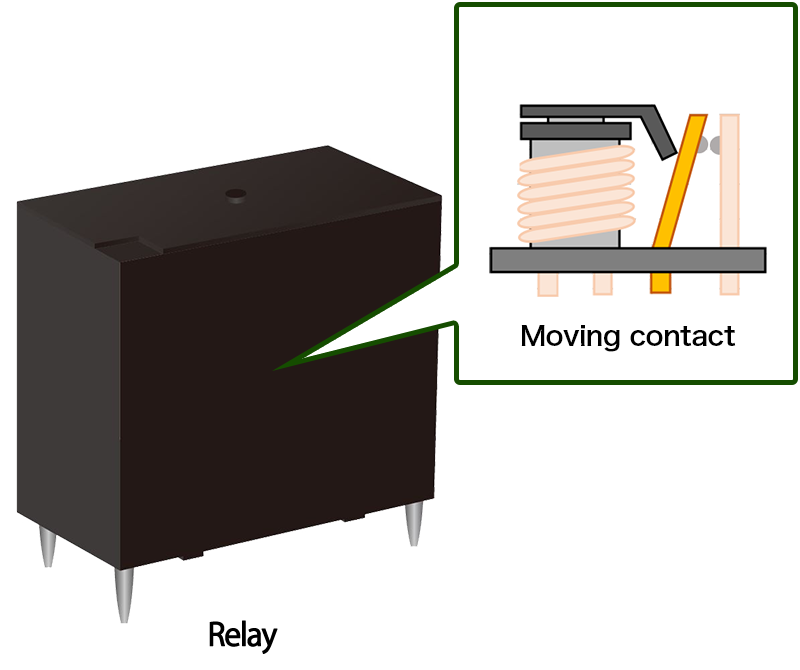

It is used for Moving contact for relays due to its high Electrical conductivity , Strength and Fatigue resistance.

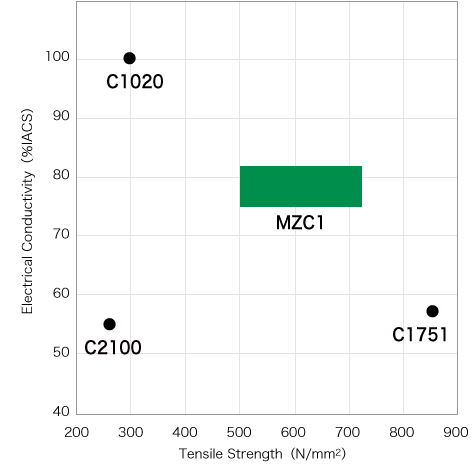

MZC 1 is a chromium · zirconium type copper alloy, and is a high strength · highly conductive type copper alloy which achieves both tensile strength of 600 MPa and conductivity of 80% IACS. As an industrial material, it is regarded as one of the copper alloy systems in a region which is closest to the ideal region. Even with its heat resistance, it has excellent characteristics and thus is suitably used under the harsh environments.

Automotive terminal, Moving conntact for relay, consumer terminal, PV terminal, press-fit terminal

fuse, socket, EV, terminals for HV battery, breaker, electrical and electronic parts with heat generation due to miniaturization, and the like

(Weight %)

| Cr | Zr | Si | Cu |

|---|---|---|---|

| 0.25 | 0.1 | 0.02 | Rem. |

| Property | Representative Value |

|---|---|

| Specific Gravity (297K) |

8.9 |

| Coefficient of Thermal Expansion (×10-6/K : 293~573 K) |

17.1 |

| Thermal Conductivity (W/(m・K) : 293 K) |

H;316 SH;287 |

| Volume Resistivity (µΩm : 293 K) |

H;0.021 SH;0.023 |

| Electrical Conductivity (%IACS : 293 K) |

H;82 SH;74 |

| Modulus of Elasticity (kN/mm2: 293 K) |

137 |

The mechanical properties of MZC1 are as follows.

| Temper | Typical Value | |||||

|---|---|---|---|---|---|---|

| 1/2H | H | SH | 1/2H t:0.15mm |

H t:0.15mm |

SH t:0.16mm |

|

| Tensile Strength (N/mm2) |

500~600 | 555~655 | 575~725 | 538 | 598 | 632 |

| 0.2% Yield Strength (N/mm2) |

- | - | - | 502 | 567 | 611 |

| Elongation (%) |

6以上 | 3以上 | 2以上 | 16 | 14 | 13 |

| Elastic Limit*1 Kb0.1(N/mm2) |

_ | _ | _ | (471) | (528) | (559) |

| Vickers Hardness*2 (HV) |

(130~190) | (160~220) | (170以上) | (164) | (181) | (202) |

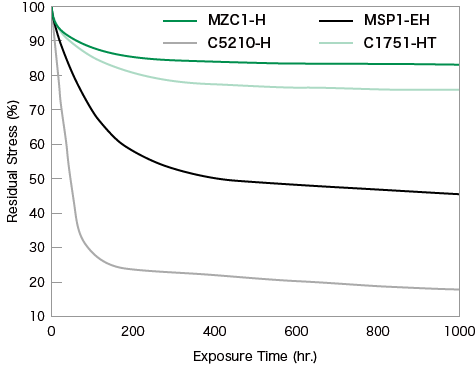

MZC 1 also exhibits excellent stress relaxation resistance characteristics as compared with beryllium copper. Excellent properties can be exhibited in the stress relaxation resistance characteristics at 200°C.

Exposure temperature: 200℃

Sampling direction: Parallel to the rolling direction

Bending stress: 80% of 0.2% yield strength

| Temper | Sampling Direction | Bending Inside Radius (mm) R | Evaluation R/t | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (to the rolling direction) | 0.0 | 0.1 | 0.125 | 0.15 | 0.2 | 0.25 | 0.4 | 0.6 | 0.8 | 1.0 | ||

| H (Thickness:0.16mm) |

0° :(Good way) |

△ | △ | △ | △ | △ | △ | ○ | ○ | ◎ | ◎ | 0.00 |

| 90° :(Bad way) |

▲ | ▲ | ▲ | ▲ | ▲ | ▲ | ▲ | △ | ○ | ◎ | 3.75 | |

| SH (Thickness:0.16mm) |

0° :(Good way) |

▲ | △ | △ | △ | △ | △ | ○ | ○ | ◎ | ◎ | 0.63 |

| 90° :(Bad way) |

▲ | ▲ | ▲ | ▲ | ▲ | ▲ | ▲ | ▲ | ▲ | △ | 6.25 | |

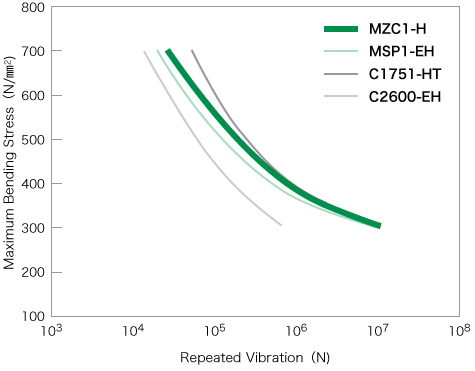

MZC 1 has almost the same fatigue characteristics as those of beryllium copper. Of course, MZC 1 does not contain hazardous substances, and thus is recommend especially for people thinking about substitution from beryllium copper.

TEL:+81-3-5252-4956

TEL:+81-72-233-9240